【Member Papers】Integration of β-Ga₂O₃ Schottky Barrier Diodes on thermoelectric modules for heat recovery and active cooling

日期:2025-10-10阅读:229

Researchers from the Xidian University have published a dissertation titled "Integration of β-Ga2O3 Schottky Barrier Diodes on thermoelectric modules for heat recovery and active cooling" in Energy Conversion and Managemen.

Project Support

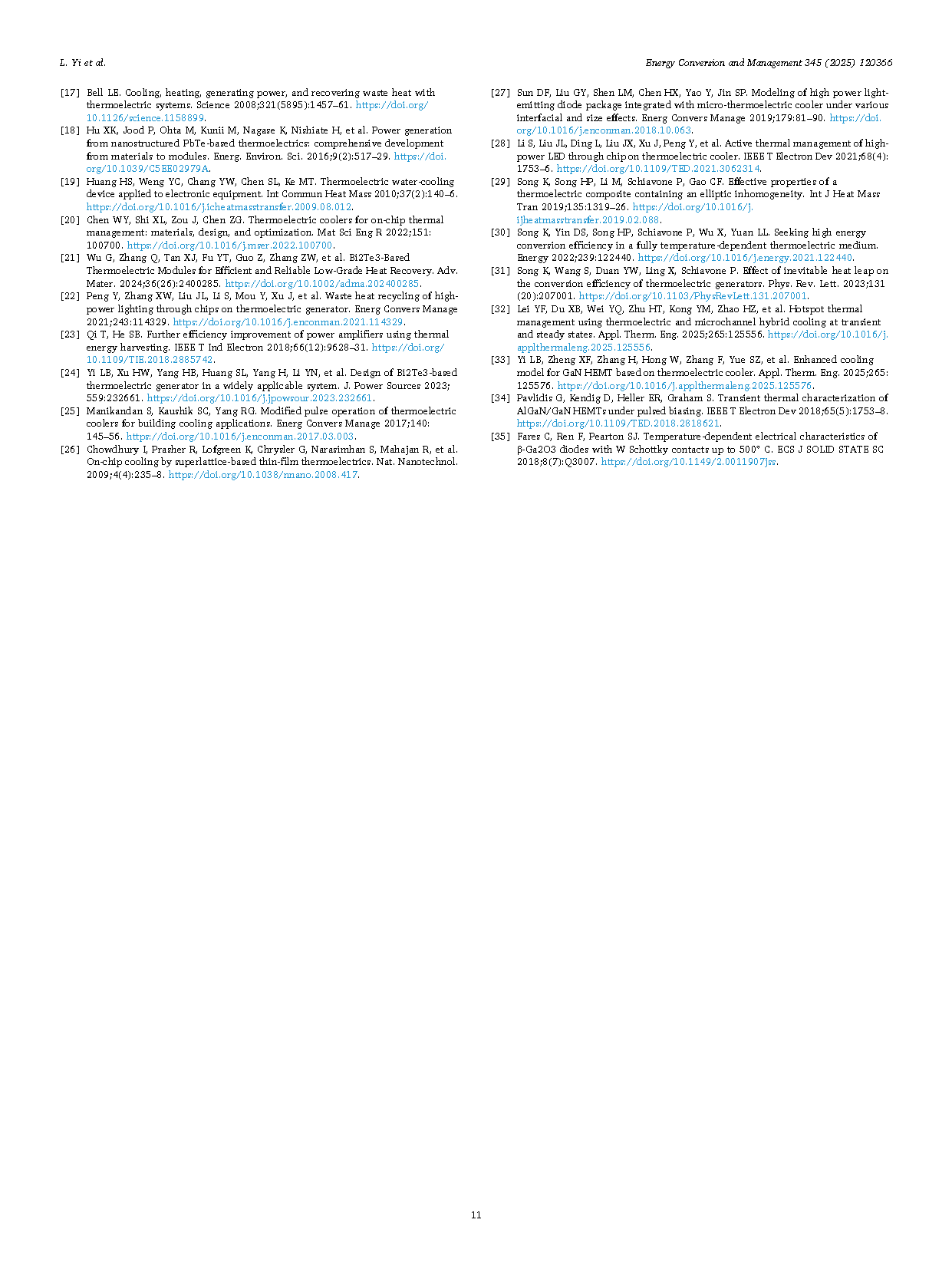

This work was supported in part by the National Natural Science Foundation of China (Grant Nos. U2241220, 62421005), in part by the Fundamental Research Funds for the Central Universities (Grant No. YJSJ25013), and in part by the Fund of National Innovation Center of Radiation Application (Grant No. KFZC2022020401).

Background

β-Ga₂O₃, as a representative ultra-wide bandgap (UWBG) semiconductor, has attracted significant attention in the field of high-power electronics due to its wide bandgap of approximately 4.8 eV, a breakdown electric field exceeding 8 MV/cm, and low intrinsic carrier concentration, offering superior voltage-blocking capability and thermal robustness compared to GaN and SiC. However, the relatively low intrinsic thermal conductivity of β-Ga₂O₃ (10–27 W·m⁻¹·K⁻¹) leads to self-heating effects and localized thermal hotspots under high-power operation, resulting in performance degradation and reliability concerns. Addressing this thermal management challenge is therefore critical. Thermoelectric modules (TEMs), with their bidirectional capability for both power generation (TEG) and cooling (TEC), provide a promising approach for waste heat recovery and active cooling in electronic devices. Previous studies have demonstrated that TEGs can convert waste heat into electrical energy, while TECs can effectively reduce junction temperature and improve device performance. Nevertheless, existing work still exhibits limitations in overall system energy balance, parameter optimization, and integrated design of bidirectional thermoelectric systems. In this work, we focus on the thermal management challenges of β-Ga₂O₃ power devices by integrating Schottky barrier diodes (SBDs) on a TEM platform and combining TEG and TEC modes to achieve synergistic optimization of waste heat recovery and active cooling. This approach provides a theoretical basis and methodological guidance for constructing high-efficiency, compact, and self-regulating thermal management systems.

Abstract

The importance of energy conversion and thermal management in power devices has driven researches toward high conversion efficiency and effective heat dissipation. This work integrates beta-phase gallium oxide (β-Ga2O3) Schottky Barrier Diodes (SBDs) on a thermoelectric module (TEM), enabling the bidirectional operation modes of heat recovery and active cooling utilizing theoretical and experimental methods. Results show that enhancing the heat exchange coefficient can significantly improve the performance of the TEM. For thermoelectric generator (TEG), the maximum net output power and net conversion efficiency increased by 0.82 W and 3.2 %, respectively, corresponding to considerable improvements of approximately 6.7 and 2.6 times compared with the natural convection condition. For thermoelectric cooler (TEC), the coefficient of performance (COP) increased from 2.88 to 3.52 by accounting for the improved output power of the SBD, indicating a 22.2 % improvement. Theoretical analysis reveals that the height of thermoelectric (TE) legs leads to peaks in output power for the TEG and cooling capacity for the TEC, while the conversion efficiency of the TEG shows an inverse trend relative to the COP of the TEC. Additionally, increasing the height of the fins and the heat exchange coefficient further enhances the performance of the TEM by enlarging temperature gradient. This work presents a new technique for improving energy efficiency and thermal performance of β-Ga2O3 SBDs.

Highlights

· A general theoretical solution for the SBD-on-TEM system is proposed.

· The heat exchange coefficient is crucial to improving system performance.

· Net output power and net conversion efficiency of the TEG are markedly improved.

· The COP of the TEC is enhanced by incorporating the improved SBD output power.

· A comprehensive optimization design for the SBD-on-TEM system is performed.

Conclusion

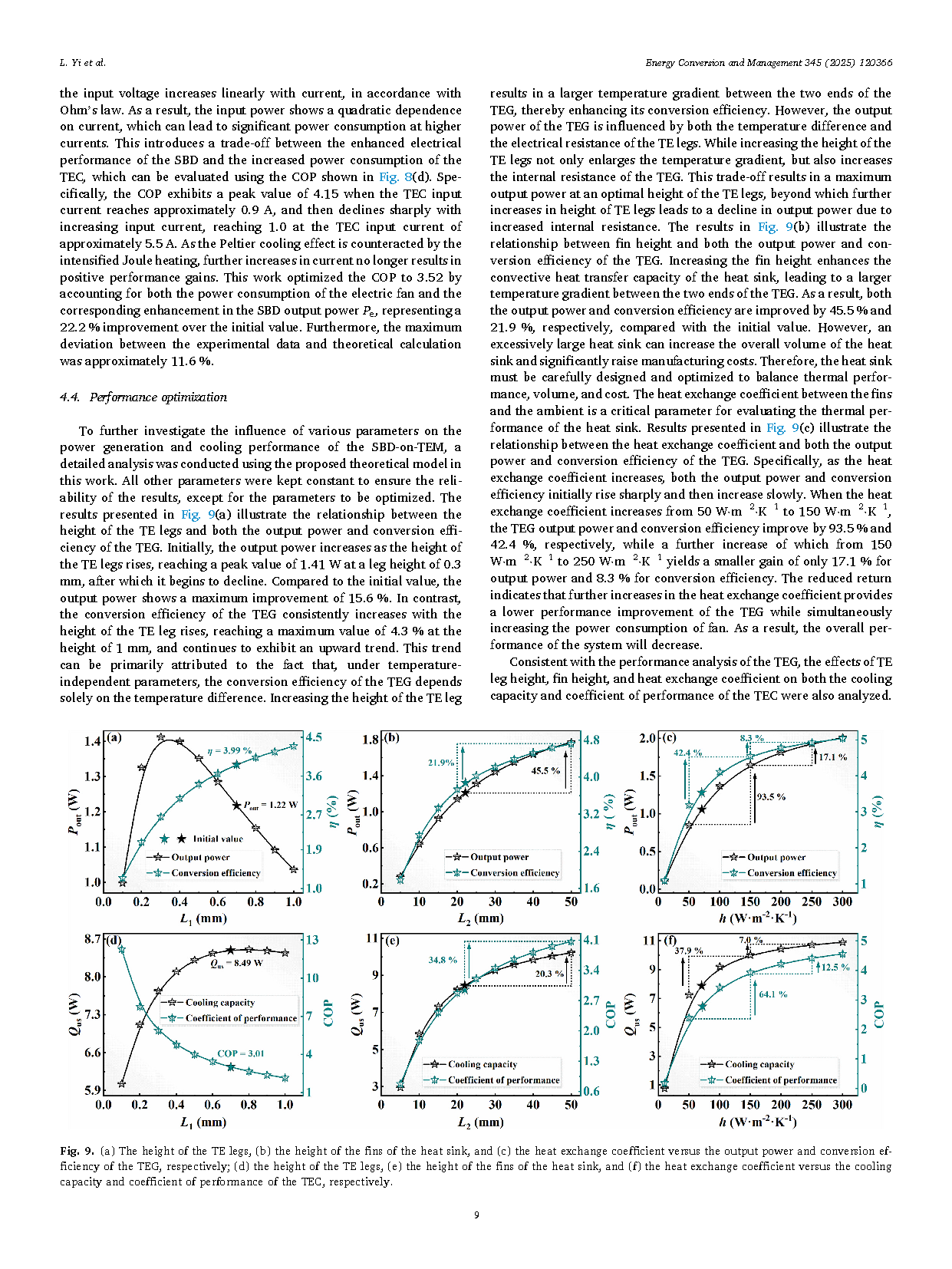

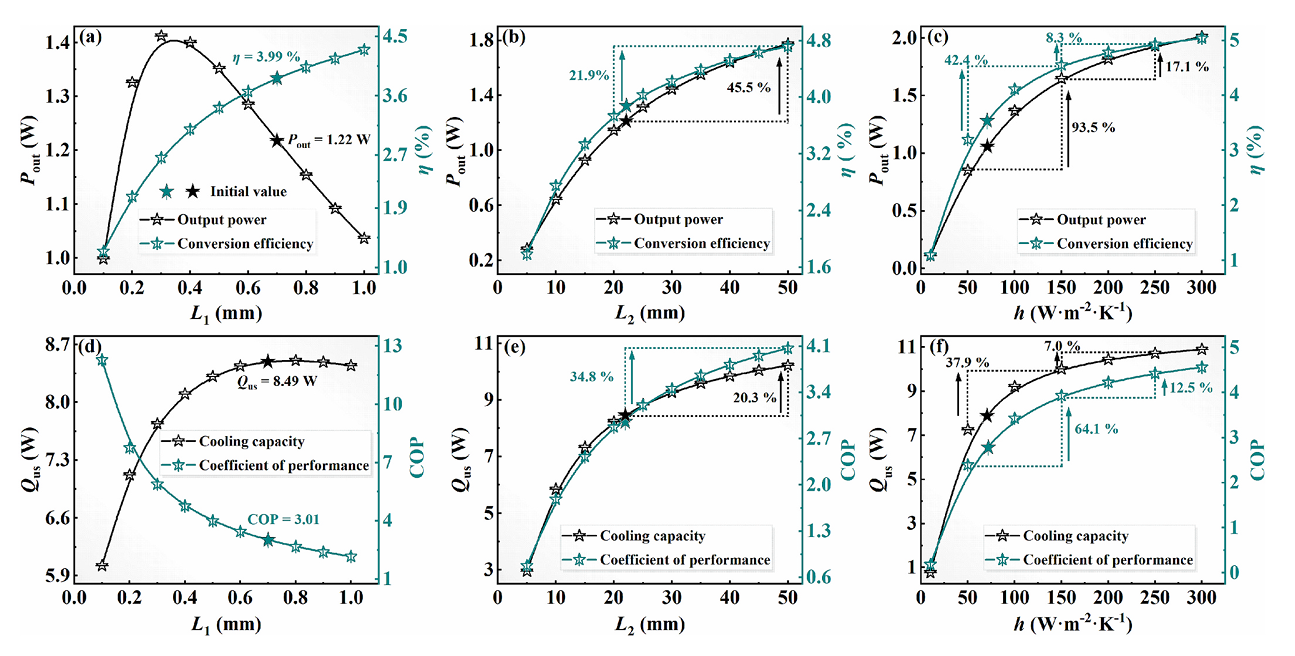

In this work, the β-Ga2O3 SBD power devices were directly bonded to the substrate of the TEM, reducing the overall thermal resistance and enhancing both thermal and electrical performance of the system. The performance of the SBD-on-TEM in both the TEG and TEC modes was comprehensively evaluated using coupled thermal-electric field models, and further validated through experiments. Results indicate that enhancing the heat exchange coefficient effectively increases the temperature gradient across the upper and lower surfaces of the TEM, thereby significantly improving its performance. In TEG mode, a net output power of 0.82 W and a net conversion efficiency of 3.2 % were achieved, corresponding to significant improvements of approximately 6.7 and 2.6 times, respectively. In TEC mode, the coefficient of performance increased from 2.88 to 3.52 when accounting for the improved electrical performance of the SBD, corresponding to a 22.2 % enhancement. Further optimization was conducted based on the proposed theoretical model. The height of the TE legs led to peaks in both output power and cooling capacity, while the conversion efficiency of the TEG and the coefficient of performance of the TEC exhibited oppo site trends with increasing TE leg height. Additionally, increasing the fin height and enhancing the heat exchange coefficient improved the performance of both the TEG and TEC by enlarging the temperature gradient. The results provide valuable guidance for the design and optimization of both heat recovery and active cooling applications in power devices.

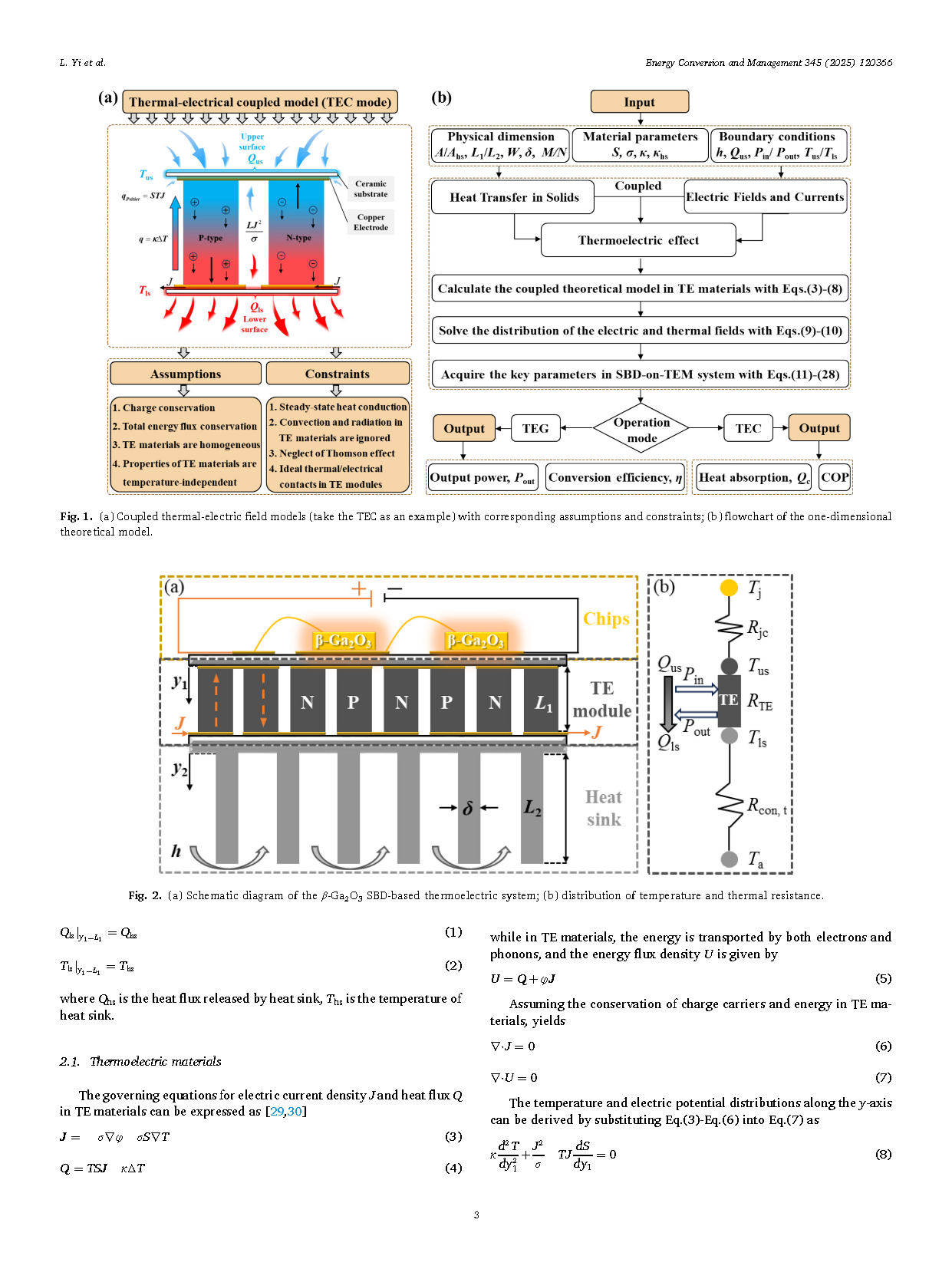

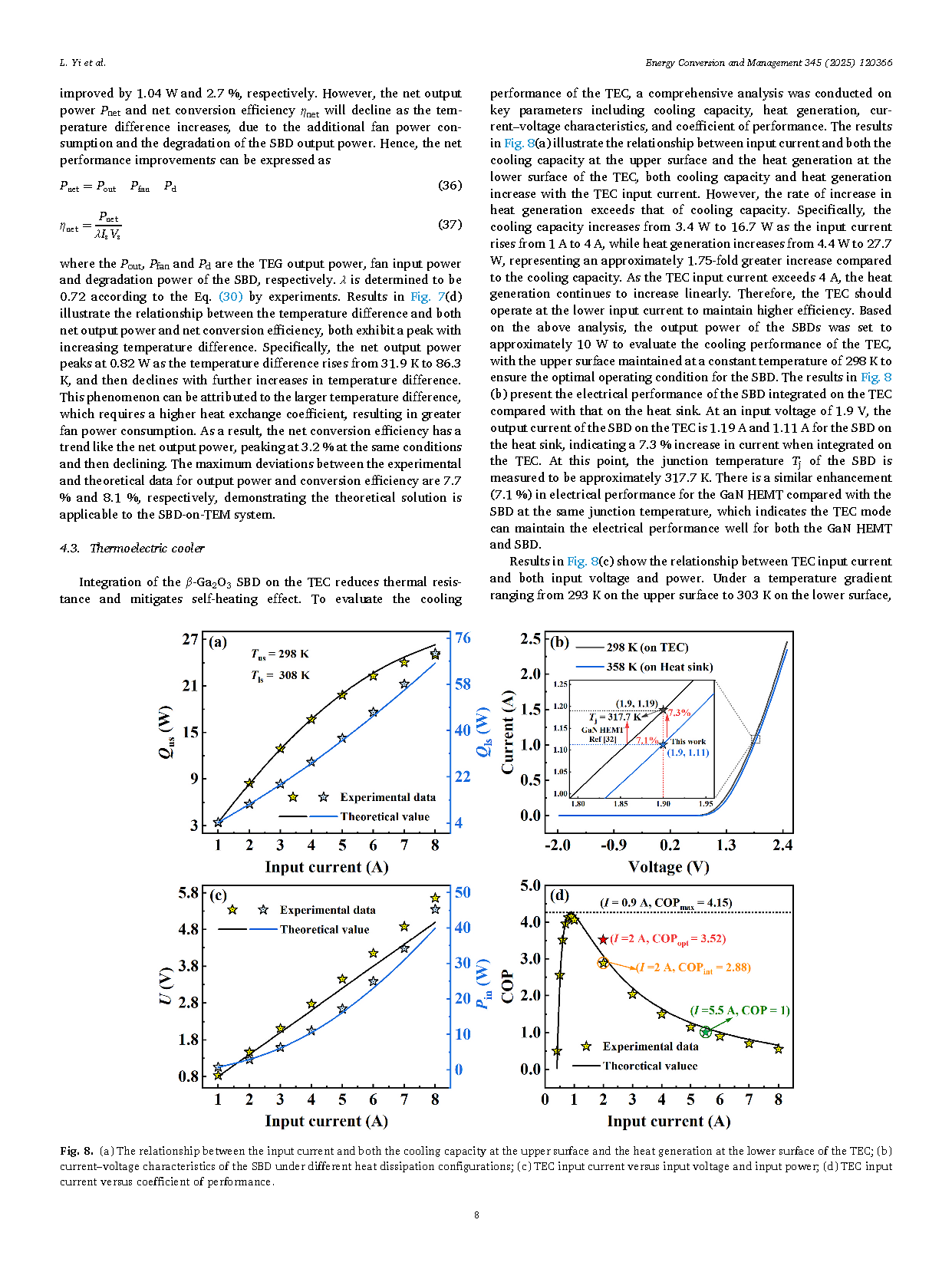

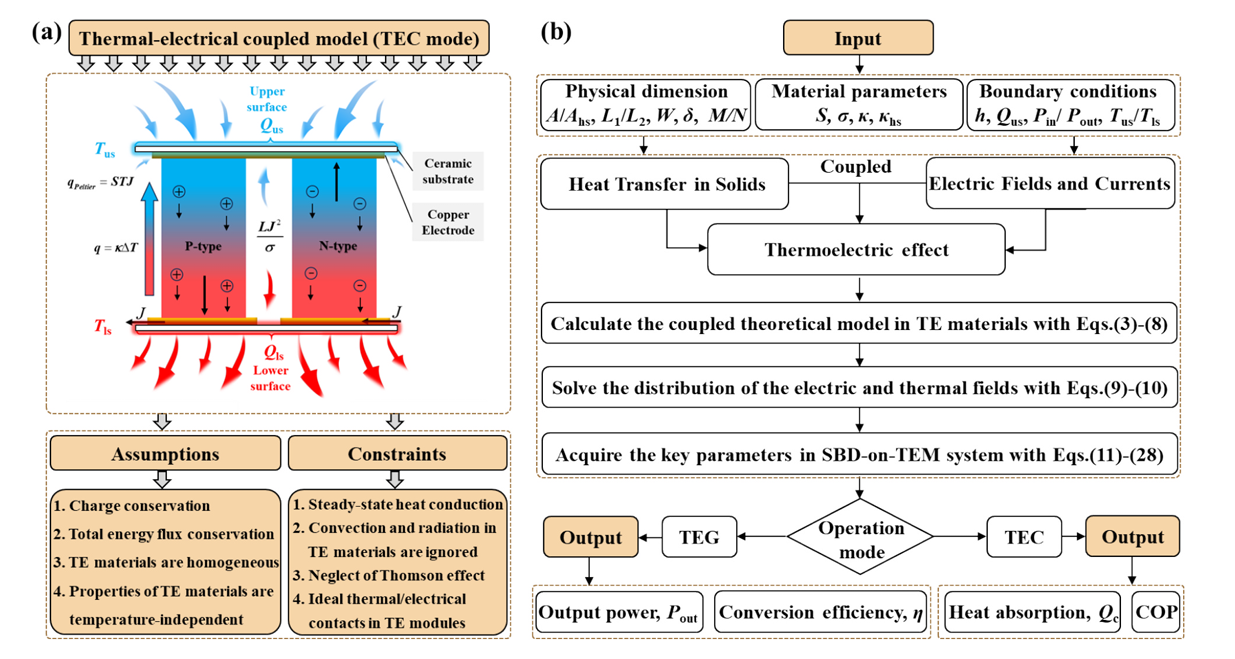

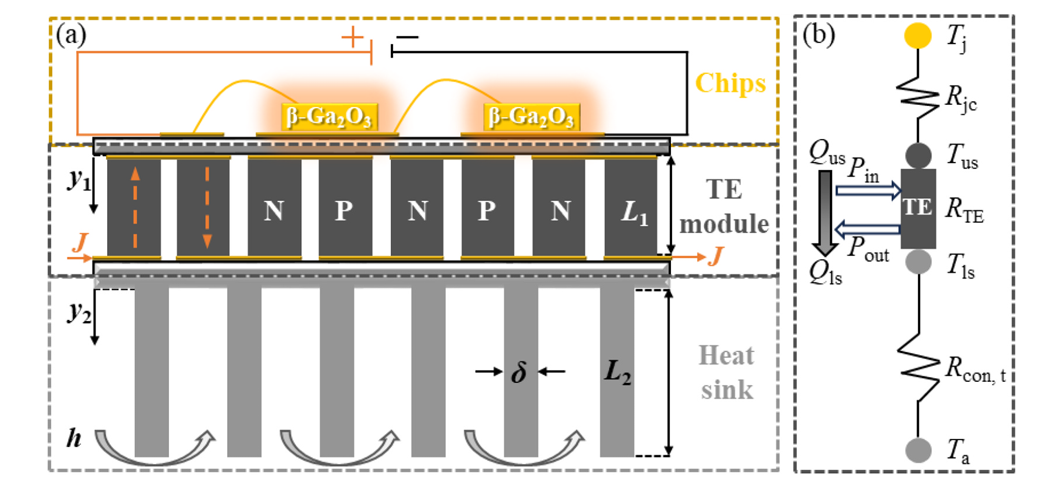

Fig. 1. (a) Coupled thermal-electric field models (take the TEC as an example) with corresponding assumptions and constraints; (b) flowchart of the one-dimensional theoretical model.

Fig. 2. (a) Schematic diagram of the β-Ga2O3 SBD-based thermoelectric system; (b) distribution of temperature and thermal resistance.

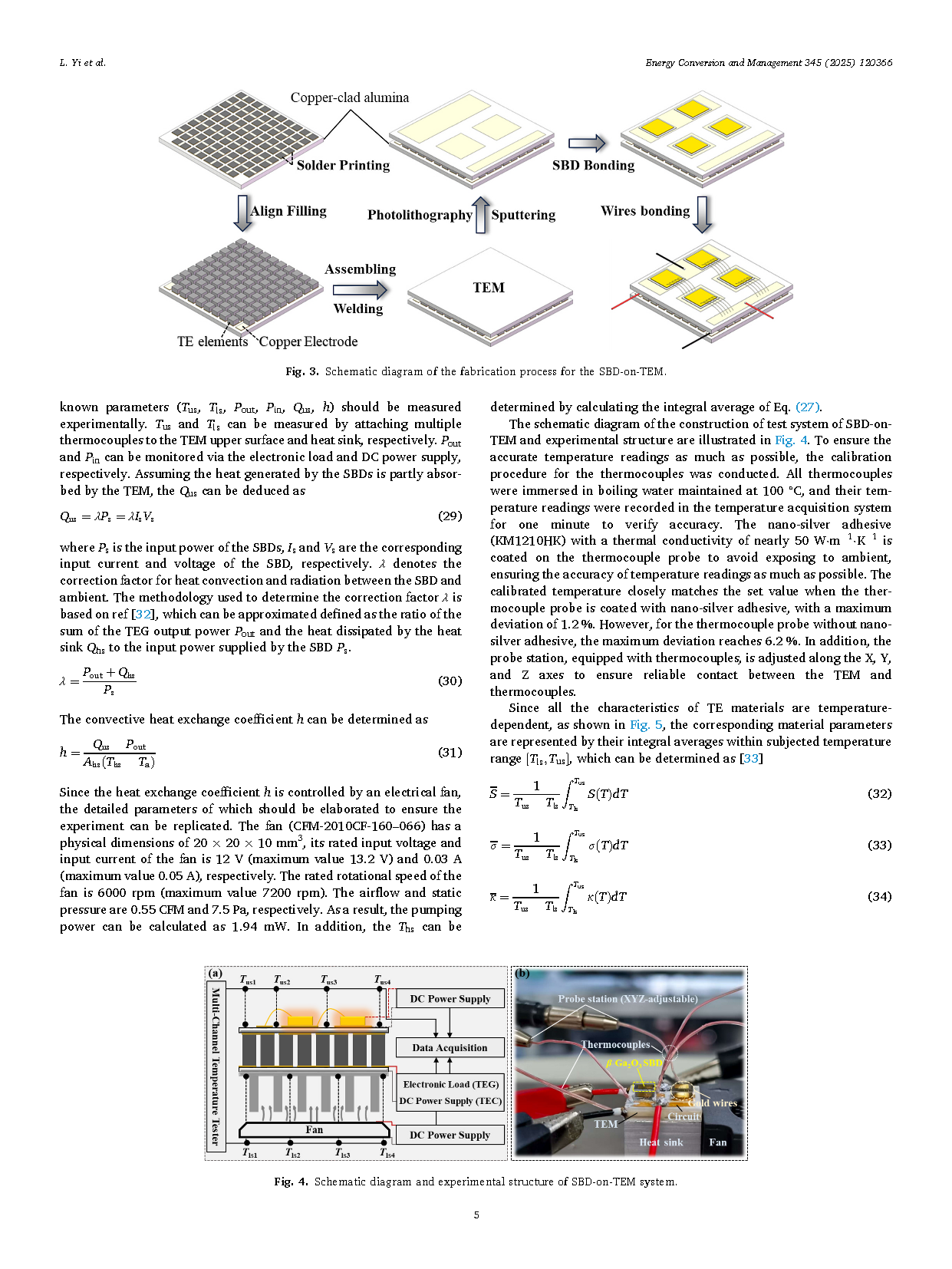

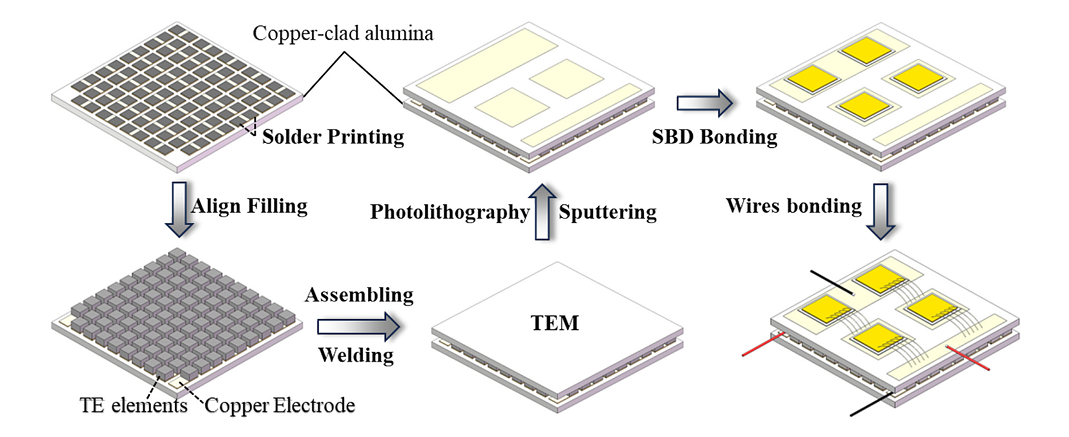

Fig. 3. Schematic diagram of the fabrication process for the SBD-on-TEM.

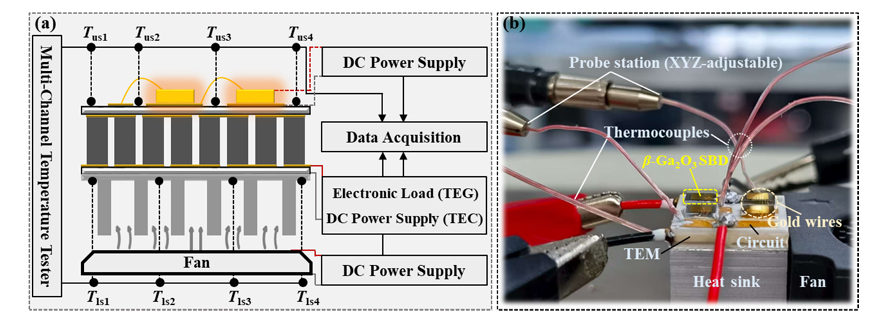

Fig. 4. Schematic diagram and experimental structure of SBD-on-TEM system.

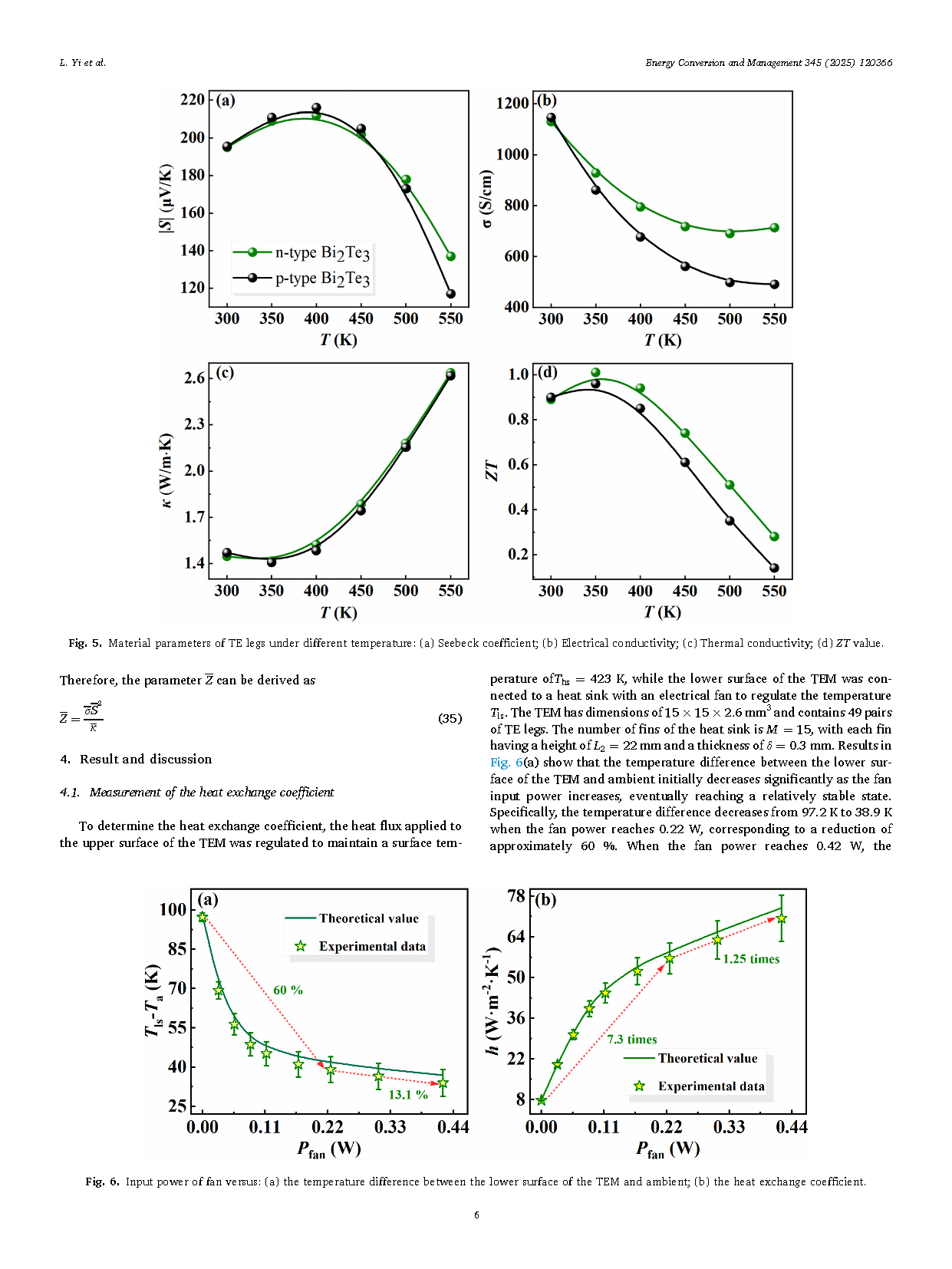

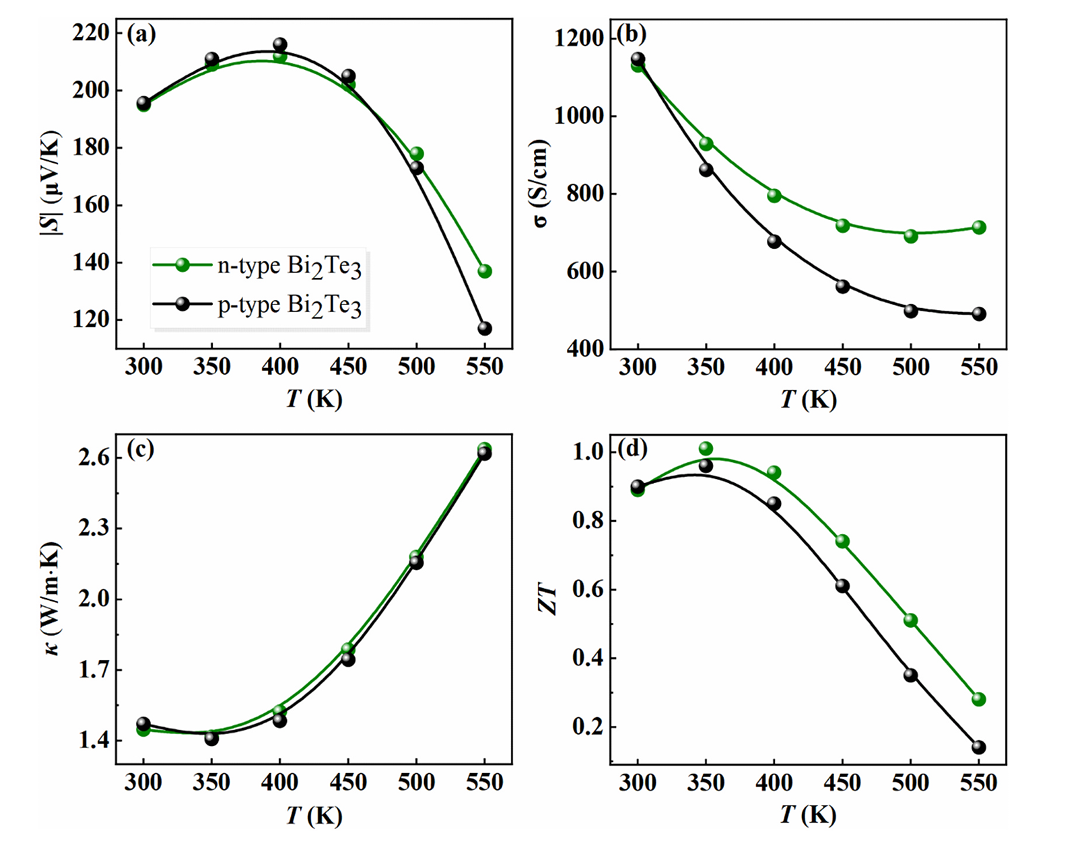

Fig. 5. Material parameters of TE legs under different temperature: (a) Seebeck coefficient; (b) Electrical conductivity; (c) Thermal conductivity; (d) ZT value.

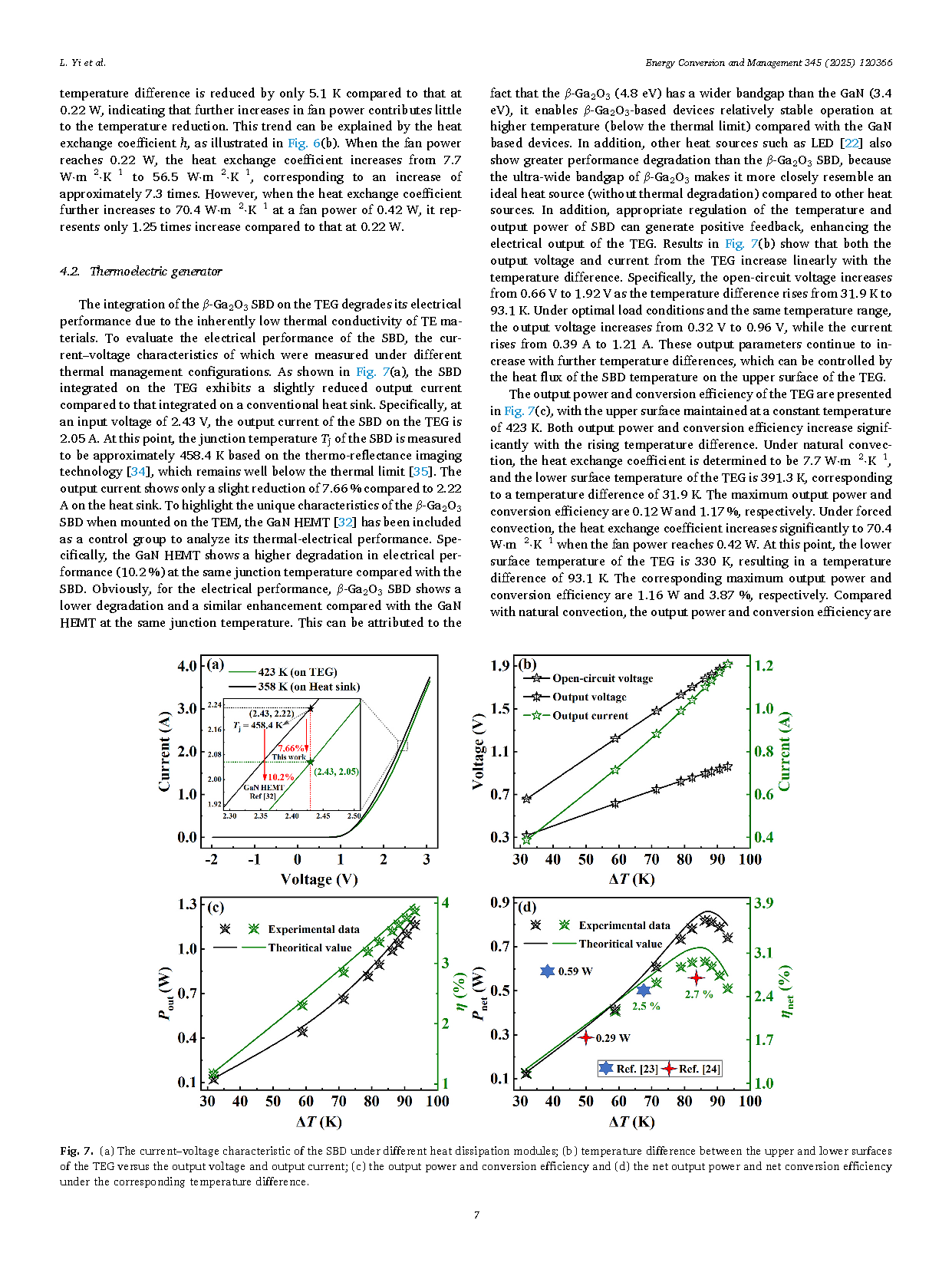

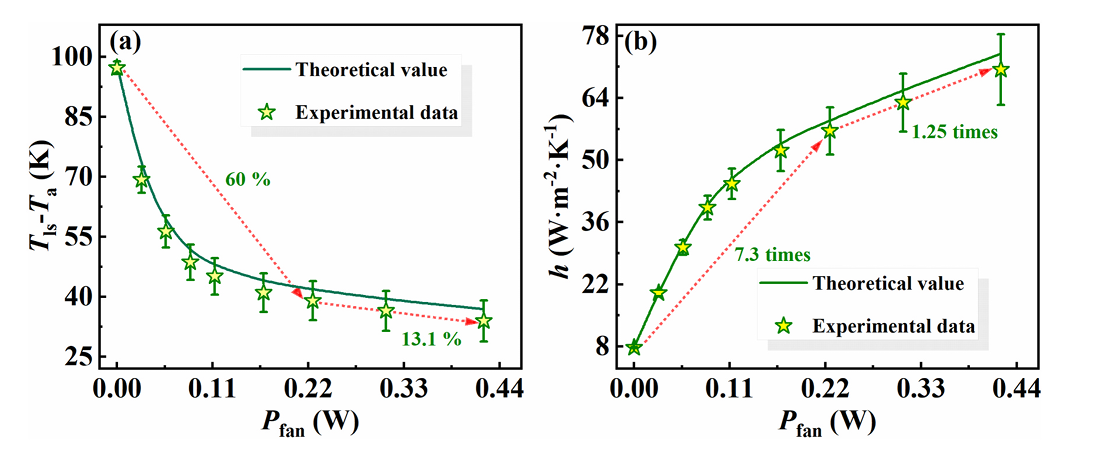

Fig. 6. Input power of fan versus: (a) the temperature difference between the lower surface of the TEM and ambient; (b) the heat exchange coefficient.

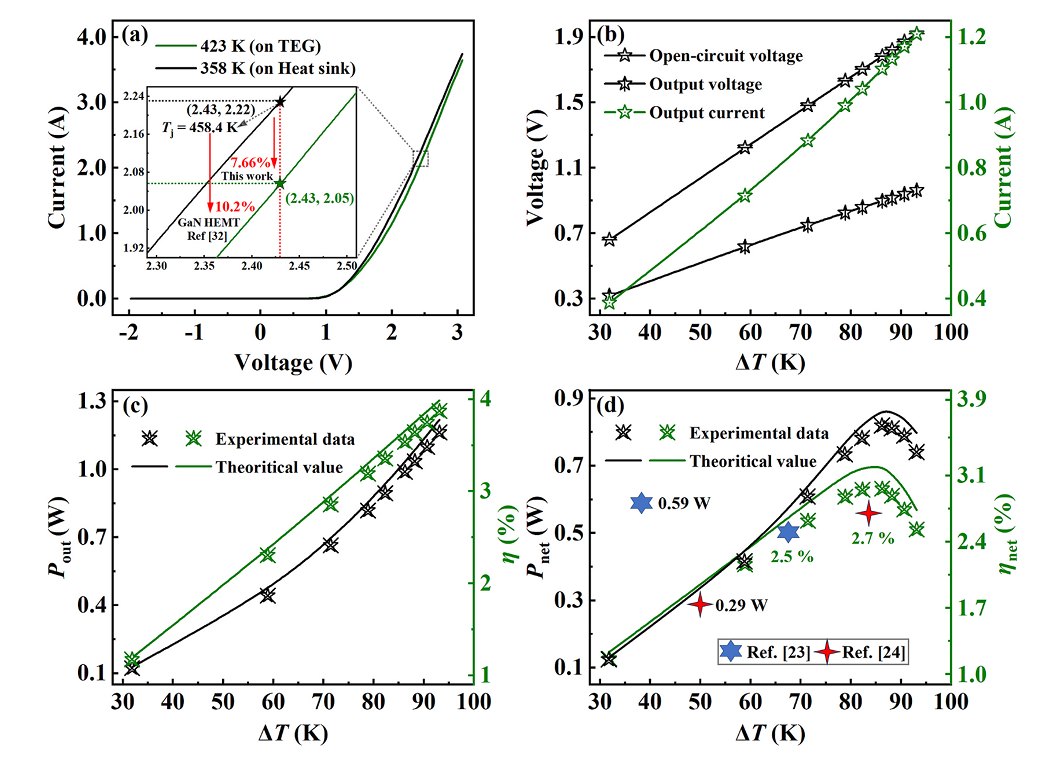

Fig. 7. (a) The current–voltage characteristic of the SBD under different heat dissipation modules; (b) temperature difference between the upper and lower surfaces of the TEG versus the output voltage and output current; (c) the output power and conversion efficiency and (d) the net output power and net conversion efficiency under the corresponding temperature difference.

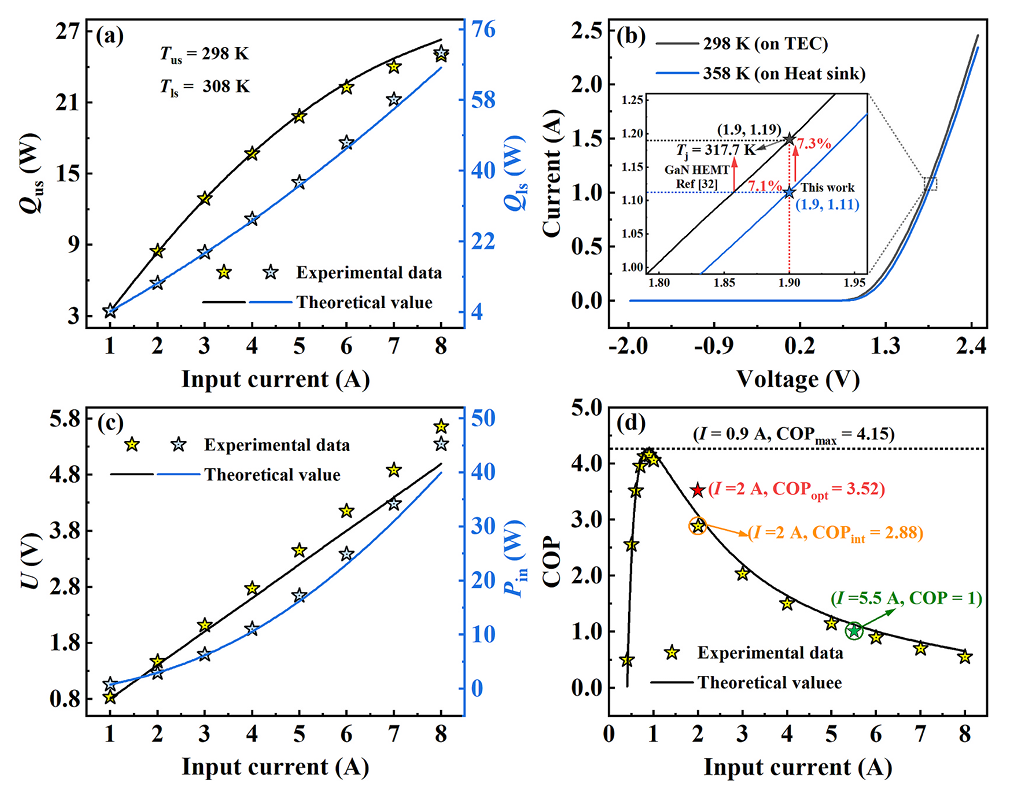

Fig. 8. (a) The relationship between the input current and both the cooling capacity at the upper surface and the heat generation at the lower surface of the TEC; (b) current–voltage characteristics of the SBD under different heat dissipation configurations; (c) TEC input current versus input voltage and input power; (d) TEC input current versus coefficient of performance.

Fig. 9. (a) The height of the TE legs, (b) the height of the fins of the heat sink, and (c) the heat exchange coefficient versus the output power and conversion efficiency of the TEG, respectively; (d) the height of the TE legs, (e) the height of the fins of the heat sink, and (f) the heat exchange coefficient versus the cooling capacity and coefficient of performance of the TEC, respectively.

DOI:

doi.org/10.1016/j.enconman.2025.120366