【Domestic Papers】Bandgap nonlinearity and composition-dependent bowing in α-(AlₓGa₁₋ₓ)₂O₃ epilayers

日期:2025-09-24阅读:203

Researchers from the Nanjing University have published a dissertation titled "Bandgap nonlinearity and composition-dependent bowing in α-(AlxGa1−x)2O3 epilayers" in The Journal of Chemical Physics.

Project Support

This work was supported by the National Key R&D Program of China (Grant No. 2022YFB3605403) and the National Natu ral Science Foundation of China (Grant Nos. 62425403, 62234007, 62293521, U21A20503, and U21A2071).

Background

Ultrawide-bandgap semiconductors, such as Ga2O3 and AlN, hold significant promise for high-power, high-frequency electronic devices and deep-ultraviolet photodetectors. However, β-Ga2O3 faces phase instability and strain-induced issues at high aluminum content, limiting further performance enhancements. In contrast, α-Ga2O3 enables stable epitaxial growth across the full range of Al composition, offering a pathway for high-performance power and optoelectronic devices. Precise alloy engineering and bandgap tailoring of α-(AlxGa1−x)2O3 allow optimization of crystalline quality, thermal stability, and electronic/optical properties, providing a solid foundation for the design and application of next-generation ultrawide-bandgap devices.

Abstract

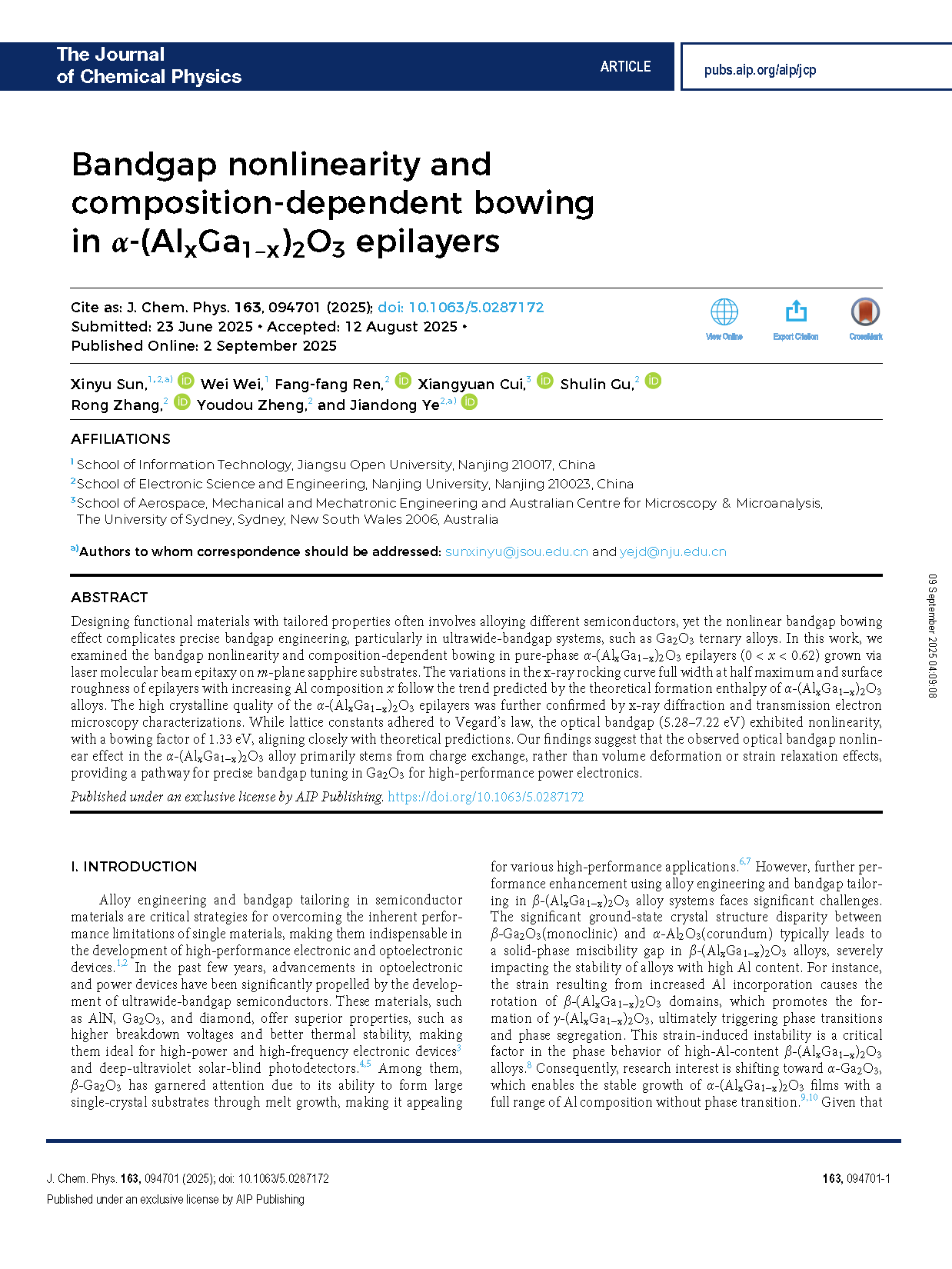

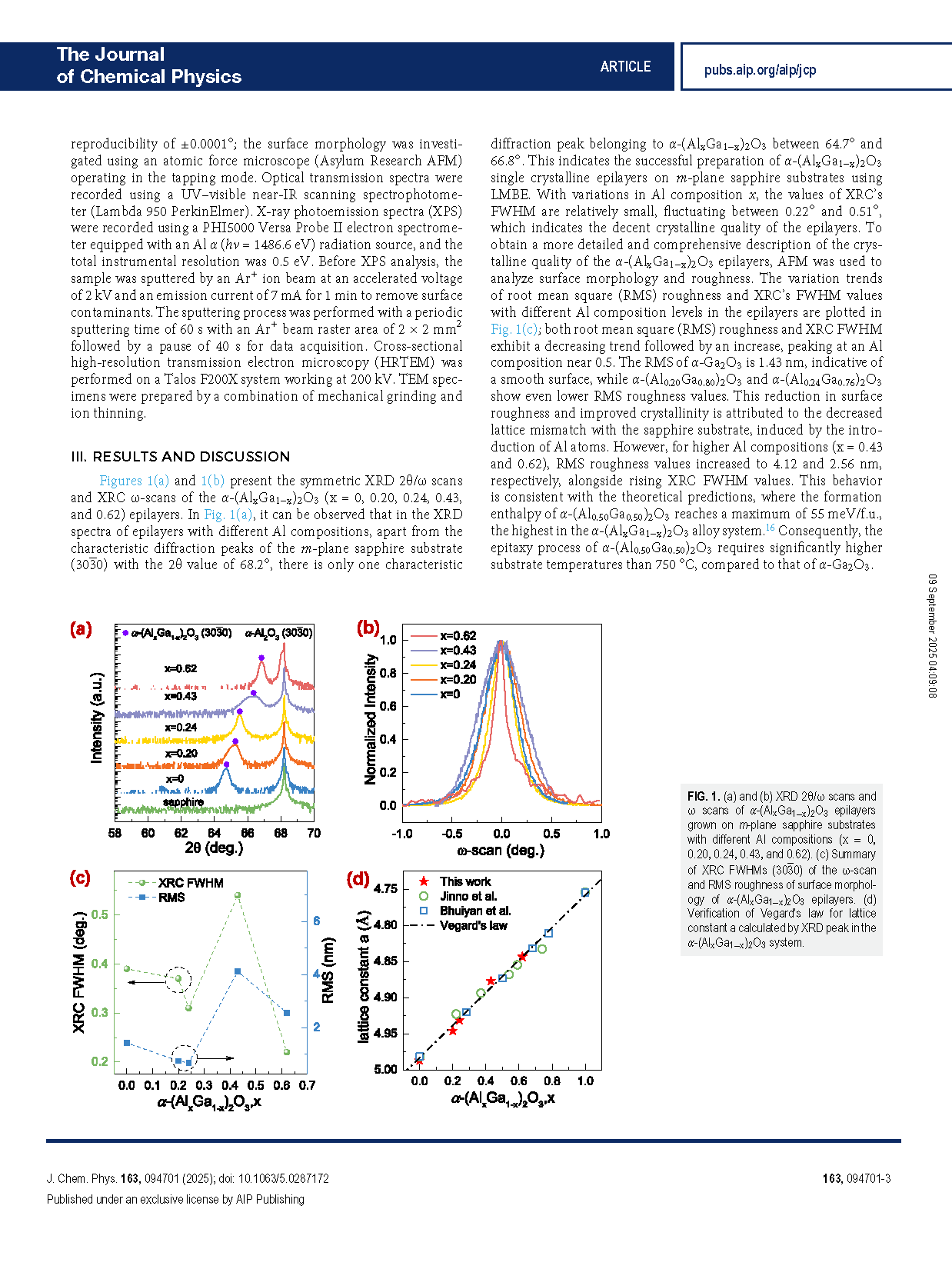

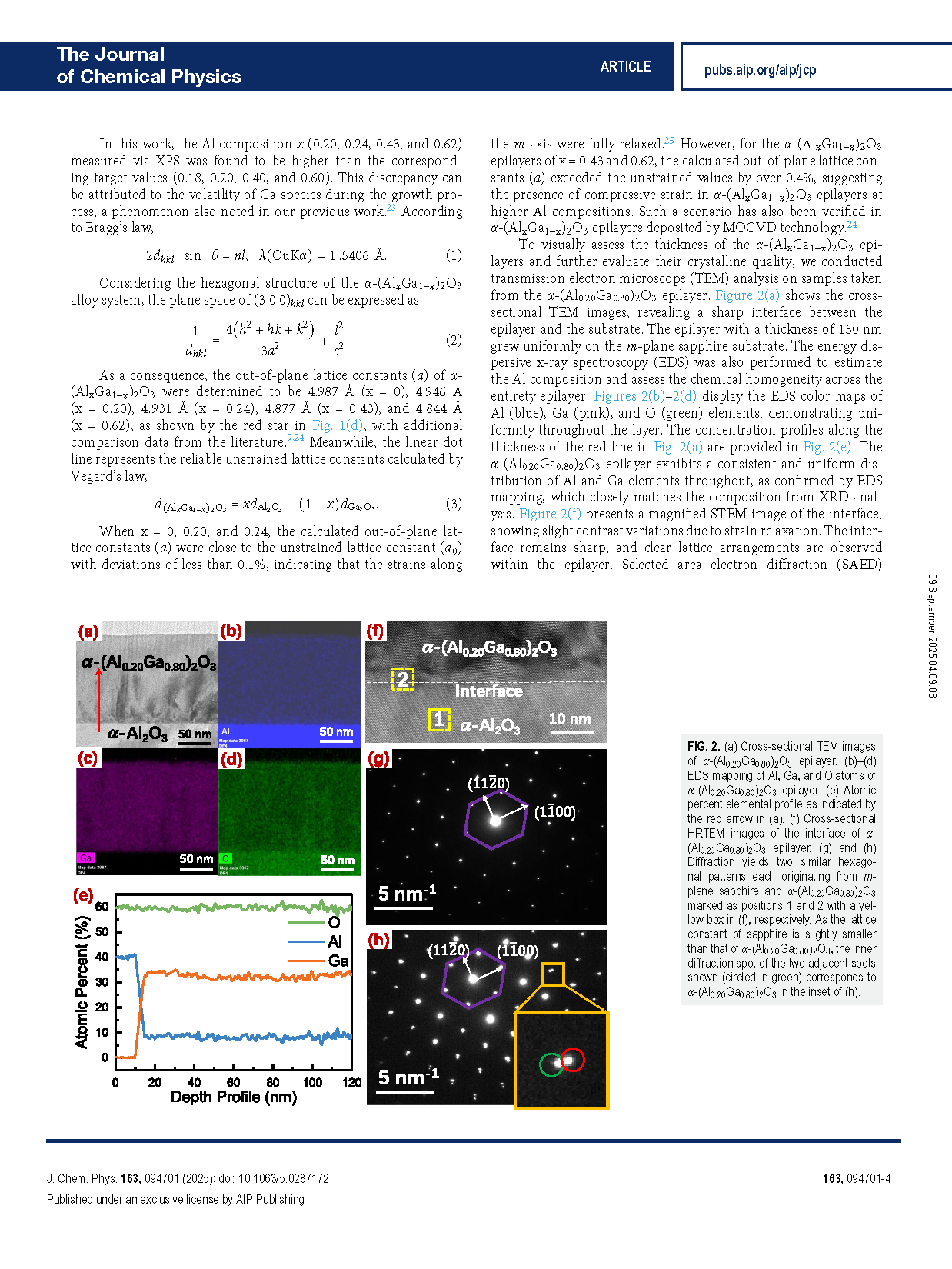

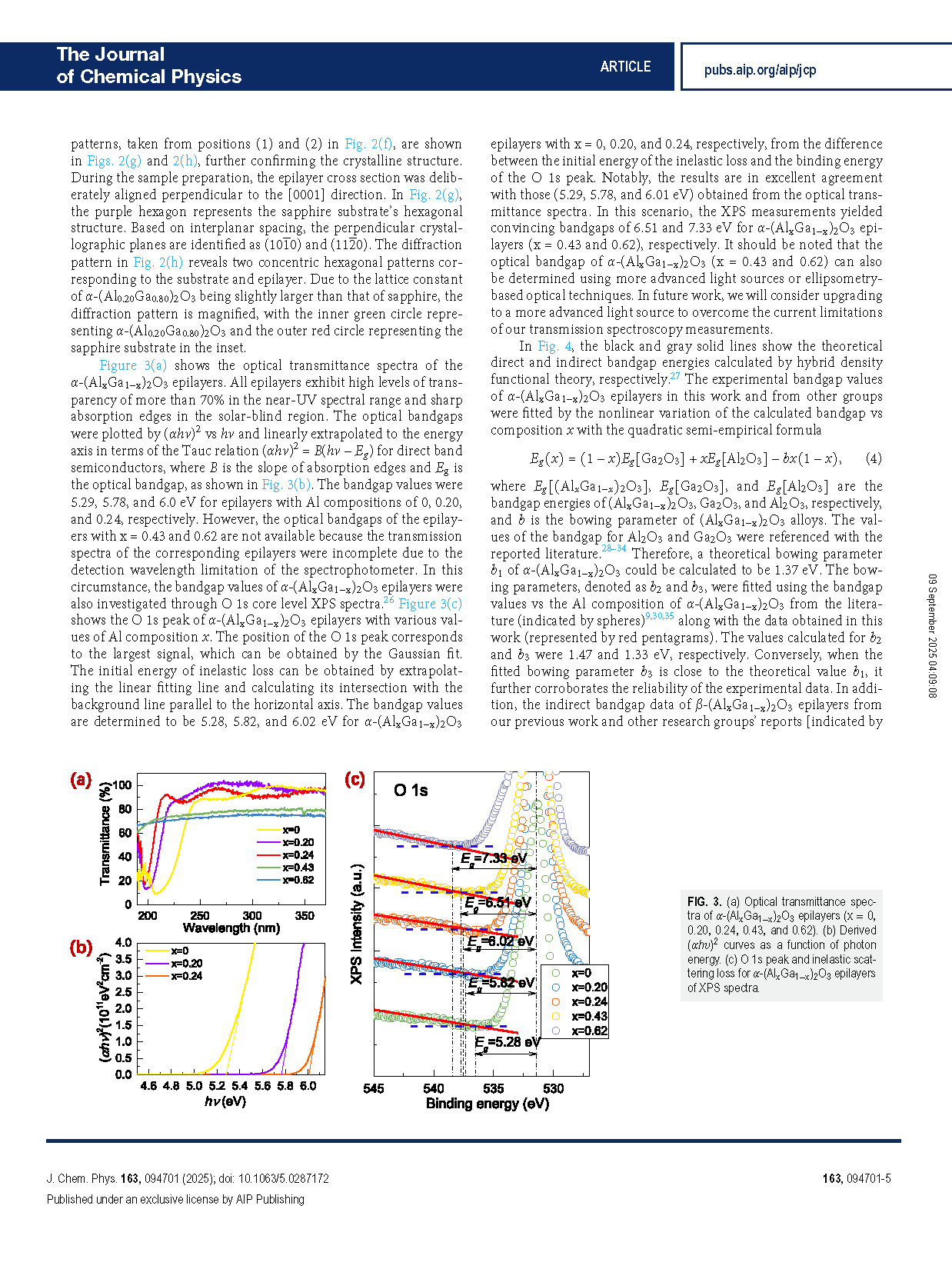

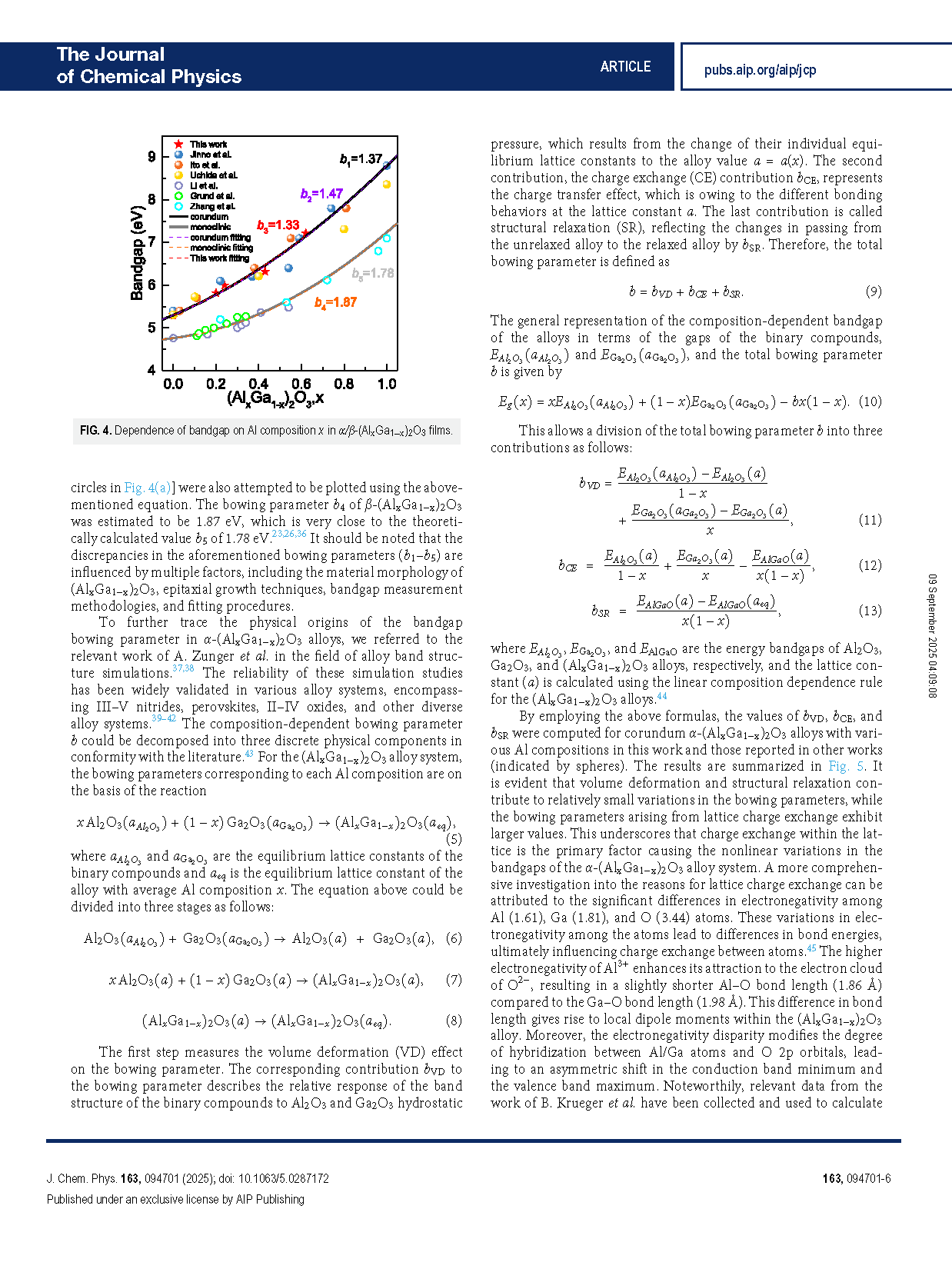

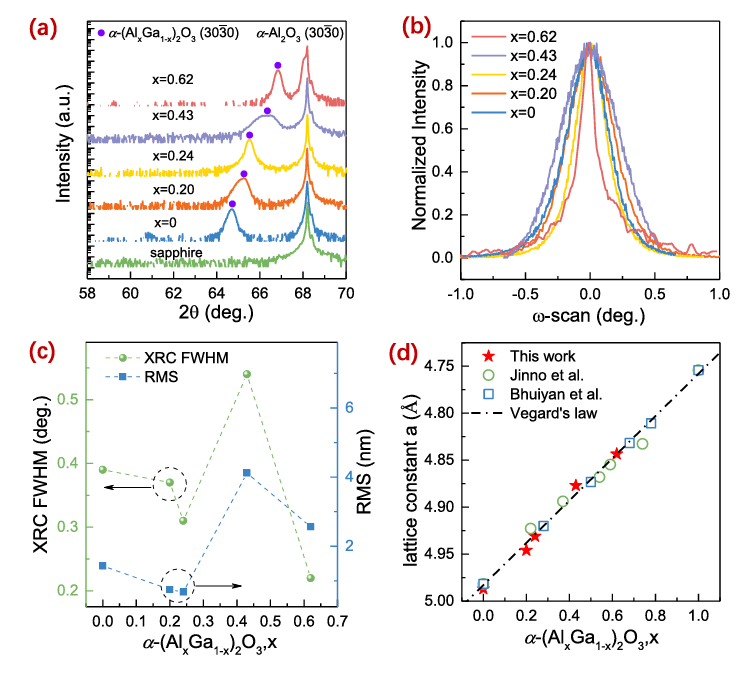

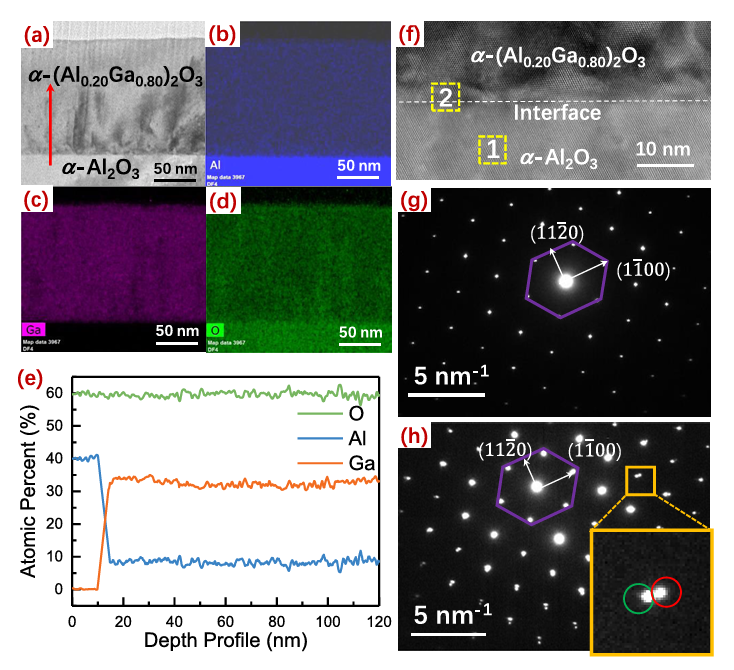

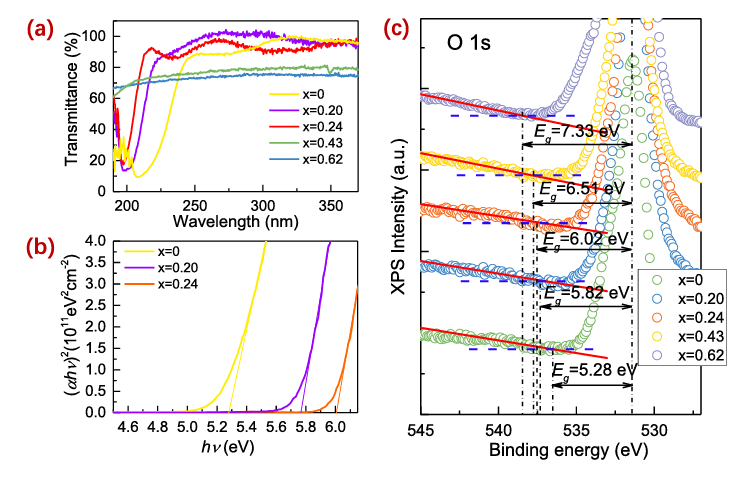

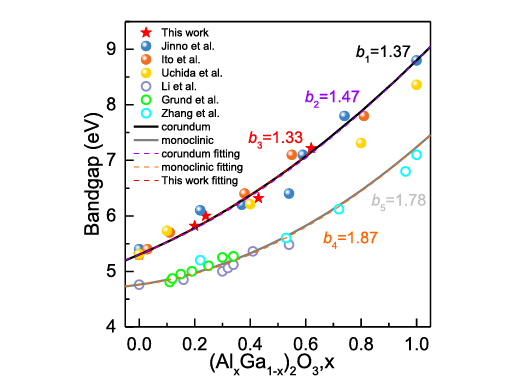

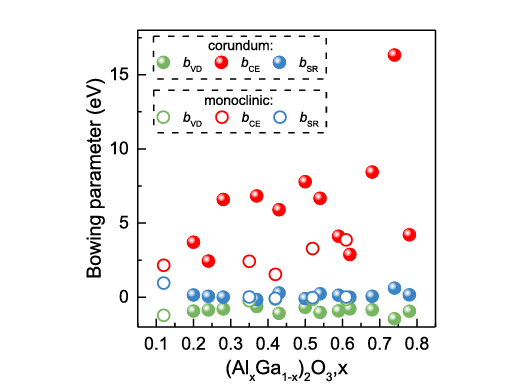

Designing functional materials with tailored properties often involves alloying different semiconductors, yet the nonlinear bandgap bowing effect complicates precise bandgap engineering, particularly in ultrawide-bandgap systems, such as Ga2O3 ternary alloys. In this work, we examined the bandgap nonlinearity and composition-dependent bowing in pure-phase α-(AlxGa1−x)2O3 epilayers (0 < x < 0.62) grown via laser molecular beam epitaxy on m-plane sapphire substrates. The variations in the x-ray rocking curve full width at half maximum and surface roughness of epilayers with increasing Al composition x follow the trend predicted by the theoretical formation enthalpy of α-(AlxGa1−x)2O3 alloys. The high crystalline quality of the α-(AlxGa1−x)2O3 epilayers was further confirmed by x-ray diffraction and transmission electron microscopy characterizations. While lattice constants adhered to Vegard’s law, the optical bandgap (5.28–7.22 eV) exhibited nonlinearity, with a bowing factor of 1.33 eV, aligning closely with theoretical predictions. Our findings suggest that the observed optical bandgap nonlinear effect in the α-(AlxGa1−x)2O3 alloy primarily stems from charge exchange, rather than volume deformation or strain relaxation effects, providing a pathway for precise bandgap tuning in Ga2O3 for high-performance power electronics.

Conclusion

In summary, we successfully grew single-crystal α-(AlxGa1−x)2O3 (0 < x < 0.62) epilayers on m-plane sapphire substrates by LMBE. HRXRD and XPS analyses confirm that the lattice constants of α-(AlxGa1−x)2O3 follow Vegard’s law with no phase transition as Al composition increases. Combining trans mission spectroscopy and detailed XPS analysis, it was observed that the bandgaps of α-(AlxGa1−x)2O3varied continuously in the range of 5.28–7.33 eV, displaying nonlinearity characteristics. The bowing parameters for the nonlinear bandgap variation of α-(AlxGa1−x)2O3 were calculated, and their physical origins were thoroughly investigated. Using three distinct sources and employing Zunger’s approach, it was confirmed that the primary mechanism responsible for the nonlinear bandgap shift in α-(AlxGa1−x)2O3 alloys is charge exchange within the lattice. These results would pave the way for application on high-power electronic devices and vacuum ultraviolet photonic devices for α-(AlxGa1−x)2O3’s bandgaps are wider than those of all materials available to date.

FIG. 1. (a) and (b) XRD 2θ/ω scans and ω scans of α-(AlxGa1−x)2O3 epilayers grown on m-plane sapphire substrates with different Al compositions (x = 0, 0.20, 0.24, 0.43, and 0.62). (c) Summary of XRC FWHMs (30-30) of the ω-scan and RMS roughness of surface morphology of α-(AlxGa1−x)2O3 epilayers. (d) Verification of Vegard’s law for lattice constant a calculated by XRD peak in the α-(AlxGa1−x)2O3 system.

FIG. 2. (a) Cross-sectional TEM images of α-(Al0.20Ga0.80)2O3 epilayer. (b)–(d) EDS mapping of Al, Ga, and O atoms of α-(Al0.20Ga0.80)2O3 epilayer. (e) Atomic percent elemental profile as indicated by the red arrow in (a). (f) Cross-sectional HRTEM images of the interface of α (Al0.20Ga0.80)2O3 epilayer. (g) and (h) Diffraction yields two similar hexago nal patterns each originating from m plane sapphire and α-(Al0.20Ga0.80)2O3 marked as positions 1 and 2 with a yel low box in (f), respectively. As the lattice constant of sapphire is slightly smaller than that of α-(Al0.20Ga0.80)2O3, the inner diffraction spot of the two adjacent spots shown (circled in green) corresponds to α-(Al0.20Ga0.80)2O3 in the inset of (h).

FIG. 3. (a) Optical transmittance spec tra of α-(AlxGa1−x)2O3 epilayers (x = 0, 0.20, 0.24, 0.43, and 0.62). (b) Derived (αhυ)2 curves as a function of photon energy. (c) O 1s peak and inelastic scat tering loss for α-(AlxGa1−x)2O3 epilayers of XPS spectra.

FIG. 4. Dependence of bandgap on Al composition x in α/β-(AlxGa1−x)2O3 films.

FIG. 5. Decomposition of α/β-(AlxGa1−x)2O3 bandgap bowing parameters into bVD, bCE, and bSR.

DOI:

doi.org/10.1063/5.0287172