【International Papers】On-chip real-time thermal characterization of beta gallium oxide Schottky barrier diodes

日期:2025-08-20阅读:243

Researchers from the King Abdullah University of Science and Technology (KAUST) have published a dissertation titled "On-chip real-time thermal characterization of beta gallium oxide Schottky barrier diodes" in Applied Thermal Engineering.

Background

Power electronics are the backbone of modern technology, enabling everything from electric vehicles to renewable energy systems. As demands for efficiency and power density increase, semiconductor materials with superior breakdown voltage and thermal stability are in high demand. Among these materials, beta gallium oxide (β-Ga2O3), a wide-bandgap semiconductor, has emerged as a promising candidate due to its exceptional material properties. β-Ga2O3 boasts a bandgap energy of 4.5–4.9 eV, significantly higher than that of silicon and even other wide-bandgap materials such as silicon carbide and gallium nitride. This large bandgap enables devices fabricated from β-Ga2O3 to achieve high breakdown voltages, superior thermal stability, and reduced power losses, making it particularly suited for applications in power rectifiers, RF amplifiers, and high-power switches.

Abstract

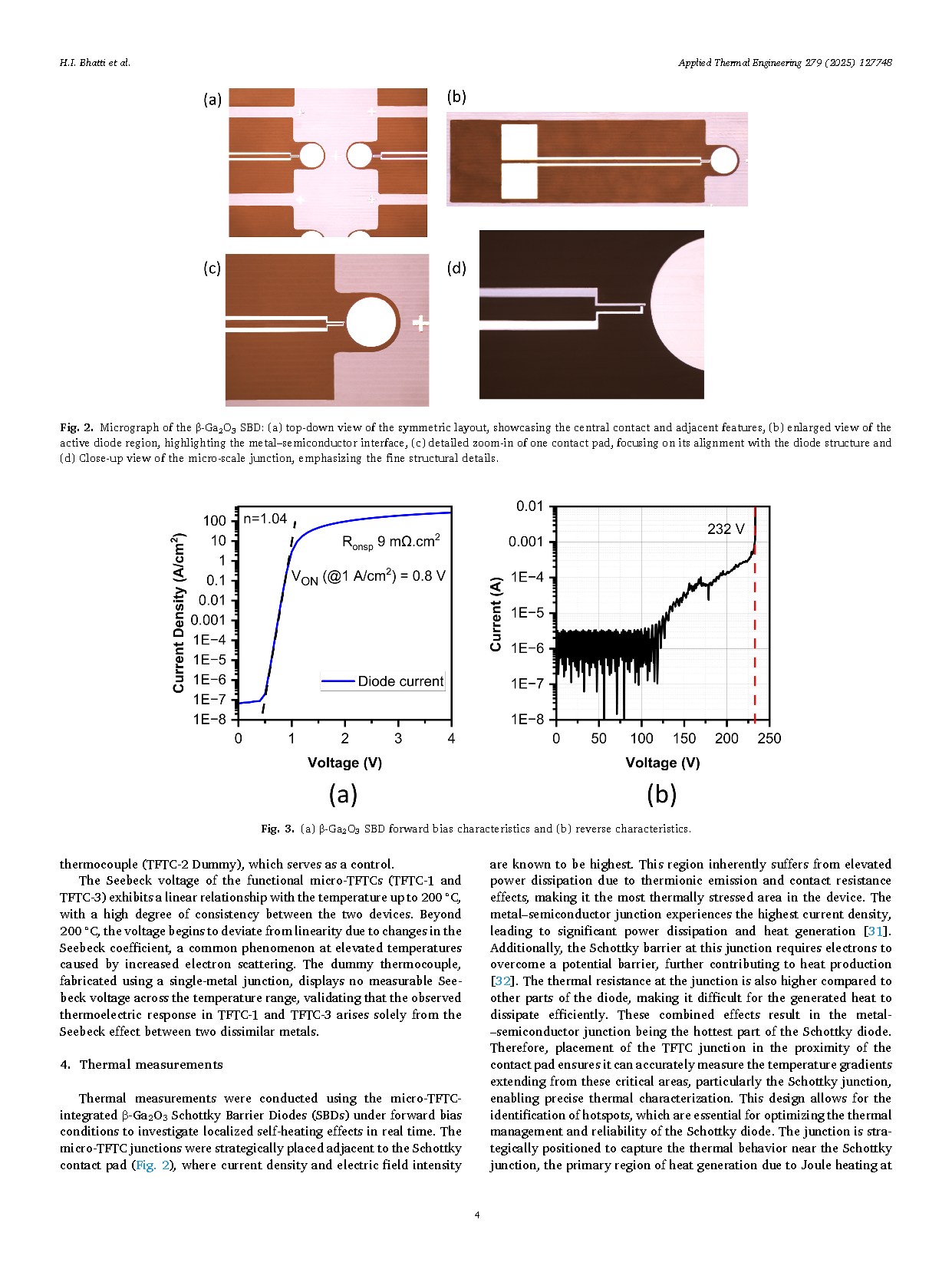

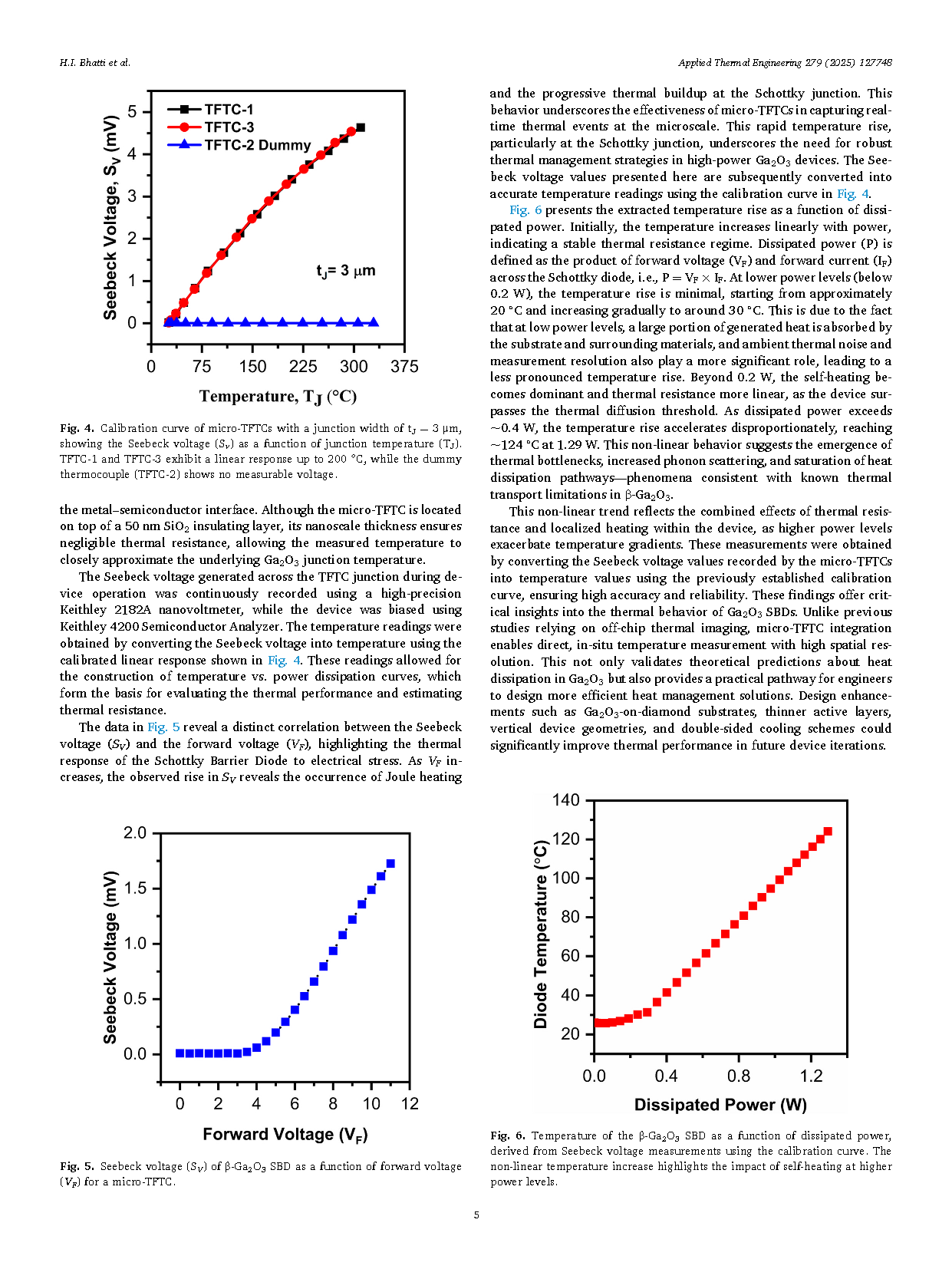

Beta gallium oxide (β-Ga2O3) is an emerging ultra-wide bandgap semiconductor with significant potential for next-generation high-power electronic applications due to its high breakdown voltage and thermal stability. However, its inherently low thermal conductivity causes substantial self-heating under operation, limiting device reliability and performance. In this study, we demonstrate a monolithically integrated micro-thin film thermocouple (micro-TFTC) system for real-time, on-chip thermal characterization of β-Ga2O3 Schottky barrier diodes (SBDs). The micro-TFTCs, based on platinum-chromium junctions, exhibit high sensitivity (19.23 ± 0.41 μV/°C) confirmed through calibrated thermal measurements. Experimental results reveal localized self-heating, with junction temperatures reaching up to 124 °C under 1.29 W power dissipation, indicating a non-linear thermal response. This integrated approach enables spatially resolved, in-situ thermal monitoring at critical device regions, offering insights into thermal management and failure mitigation strategies. The proposed technique advances the understanding of self-heating in β-Ga2O3 devices and provides a scalable pathway toward improved reliability in power electronics.

Highlights

● Monolithic micro-TFTCs were integrated on β-Ga₂O₃ SBDs for on-chip thermal sensing.

● Platinum–chromium TFTCs enable real-time junction temperature monitoring.

● Device-level thermal mapping reveals self-heating effects in β-Ga₂O₃ SBDs.

● Micro-TFTCs show high sensitivity confirmed through calibrated measurements.

● Study addresses thermal reliability challenges in ultra-wide bandgap devices.

Conclusion

In this study, an on-chip thermal characterization approach for β-Ga2O3 SBDs using monolithically integrated micro-TFTCs has been demonstrated. The findings highlight the significant self-heating effects in β-Ga2O3 SBDs, with junction temperatures rising under increasing power dissipation. The integration of micro-TFTCs enabled precise, localized, and real-time temperature monitoring at critical regions, including the Schottky junction, which is crucial for understanding and managing thermal gradients and hot-spot formation.

The experimental results revealed that temperatures near the Schottky junction reached approximately 124 °C at a power dissipation of 1.29 W, underscoring the importance of effective thermal management in high-power applications. The high sensitivity and robustness of the micro-TFTCs, validated through precise calibration, further emphasize their potential for broader applications in power electronics.

This methodology not only advances the understanding of thermal behaviors in β-Ga2O3 SBD but also paves the way for designing thermally resilient devices. Micro-TFTCs provide feedback that can be used in thermal management loops to limit prolonged exposure to high temperatures, reducing degradation and extending device lifespan. By addressing key challenges in the next generation of high-power semiconductor technologies, our work contributes to the development of more reliable and efficient power electronic systems.

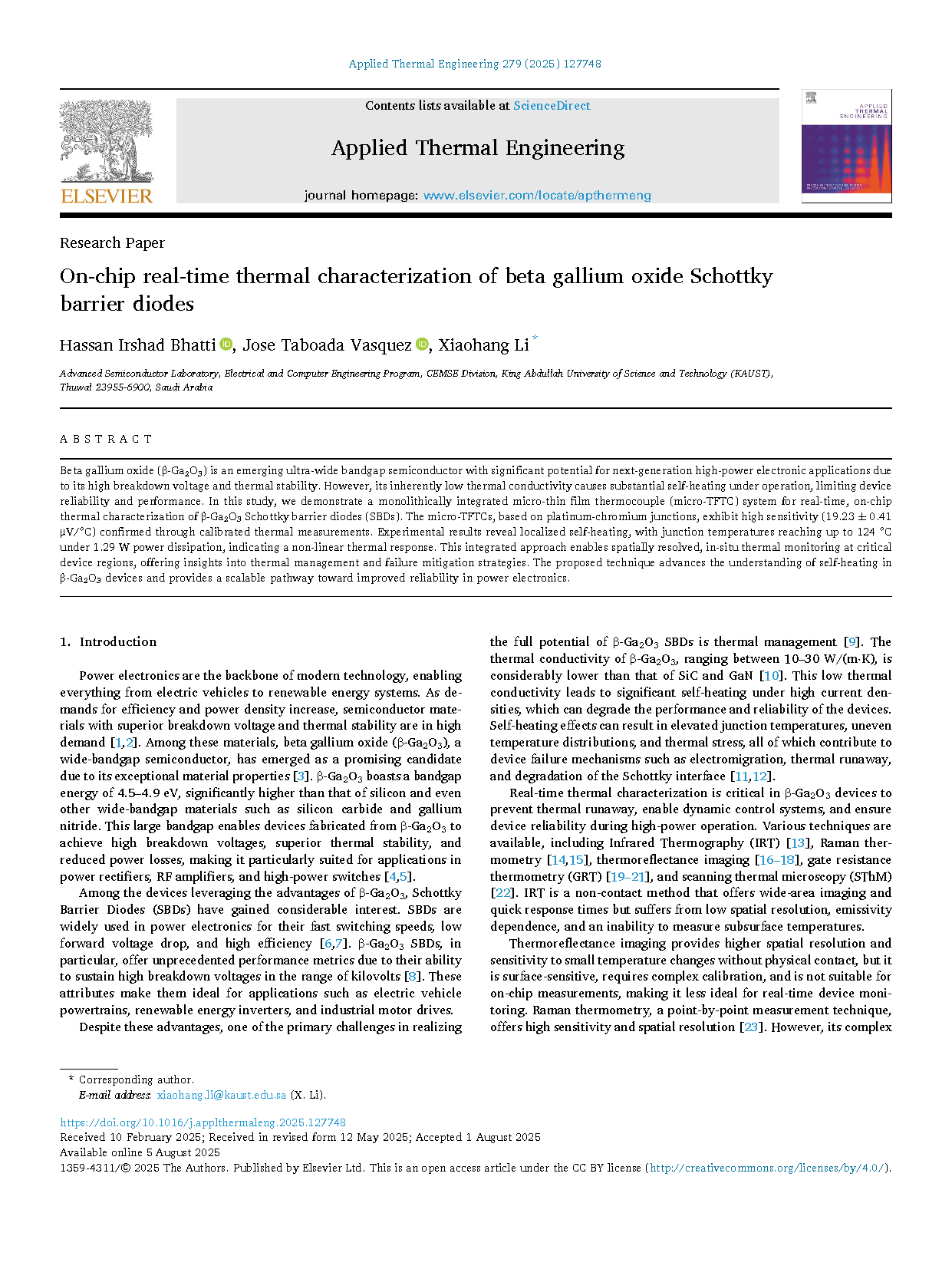

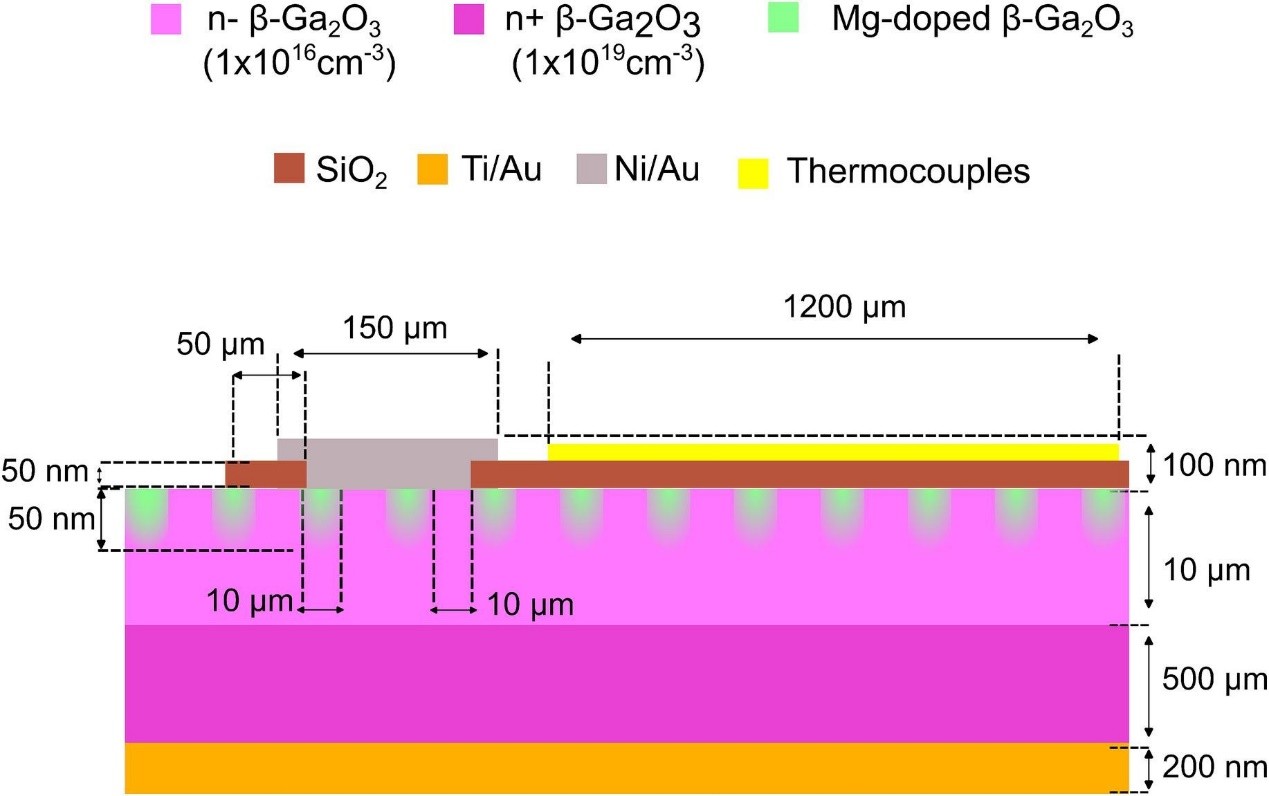

Fig. 1. Schematic of the fabricated diode with monolithically integrated micro-TFTC.

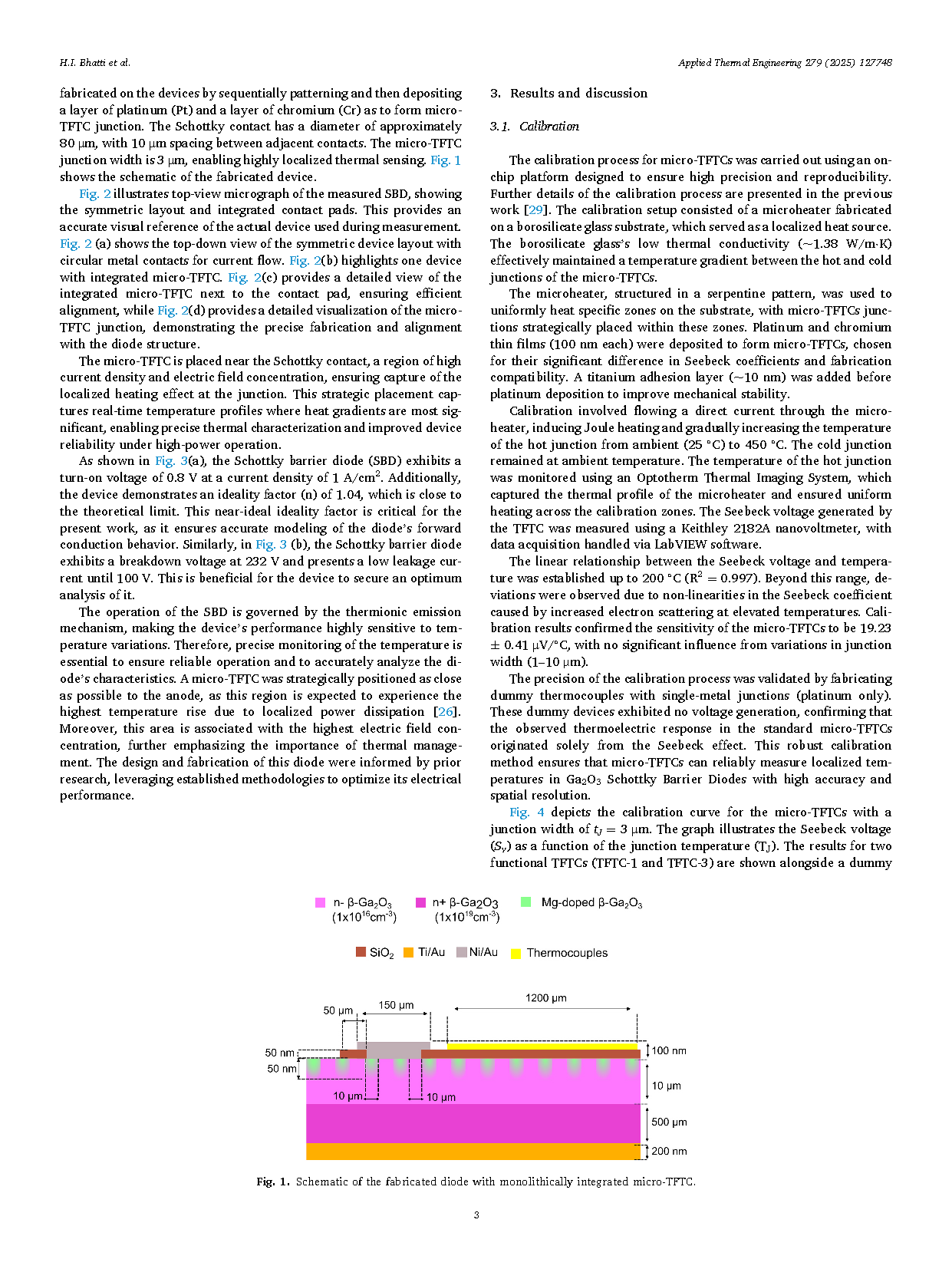

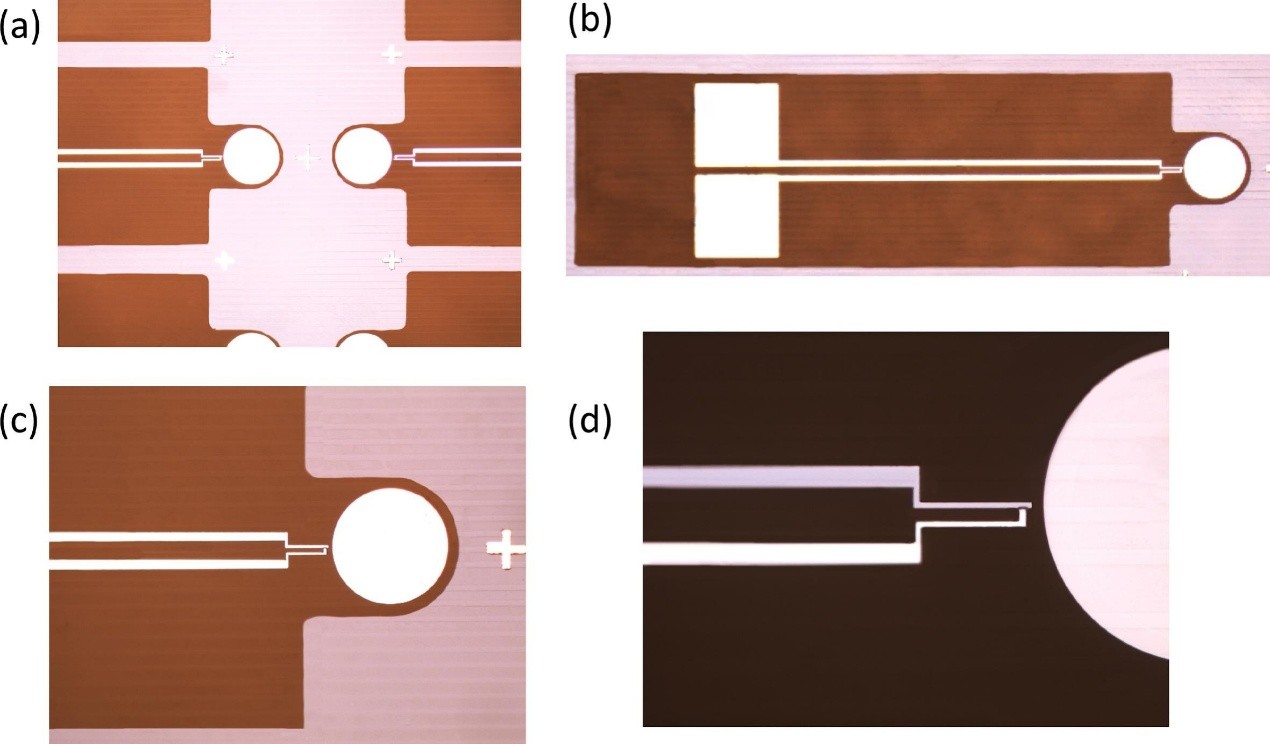

Fig. 2. Micrograph of the β-Ga2O3 SBD: (a) top-down view of the symmetric layout, showcasing the central contact and adjacent features, (b) enlarged view of the active diode region, highlighting the metal–semiconductor interface, (c) detailed zoom-in of one contact pad, focusing on its alignment with the diode structure and (d) Close-up view of the micro-scale junction, emphasizing the fine structural details.

DOI:

doi.org/10.1016/j.applthermaleng.2025.127748