【Member Papers】Active Thermal Management for β-Ga₂O₃ Schottky Barrier Diodes Based on Thermoelectric Coolers

日期:2025-07-30阅读:141

Researchers from the Xidian University have published a dissertation titled "Active Thermal Management for β-Ga2O3 Schottky Barrier Diodes Based on Thermoelectric Coolers" in IEEE Transactions on Electron Devices.

Project Support

This research is support from National Natural Science Foundation of China (Grant Number: U2241220 and 62421005)、Fundamental Research Funds for the Central Universities (Grant Number: YJSJ25013)、fund of National Innovation Center of Radiation Application (Grant Number: KFZC2022020401)、National Key Research and Development Program of China (Grant Number: 2023YFB3611900).

Background

BETA-PHASE gallium oxide (β-Ga2O3) exhibits remarkable advantages for high-voltage and high-current power device applications due to its wide bandgap of 4.8 eV, high critical breakdown field of 8 MV/cm, and high electron saturation velocity of 1.5 × 107 cm/s, which contributes a high Baliga’s figure of merit (BFOM) exceeding 3000 (320 for 4H-SiC and 860 for GaN). However, compared to 4H-SiC and GaN, the lower thermal conductivity (∼27 W/mK, around 1/20 of 4H-SiC and 1/5 of GaN) of β-Ga2O3 limits its heat dissipation during operation, leading to severe self-heating effects. This self-heating limits its electrical performance and compromises its long-term reliability. Consequently, a well-designed and efficient thermal management solution is essential to ensure the high performance and stability of β-Ga2O3 electronics while maintaining their miniaturization.

Abstract

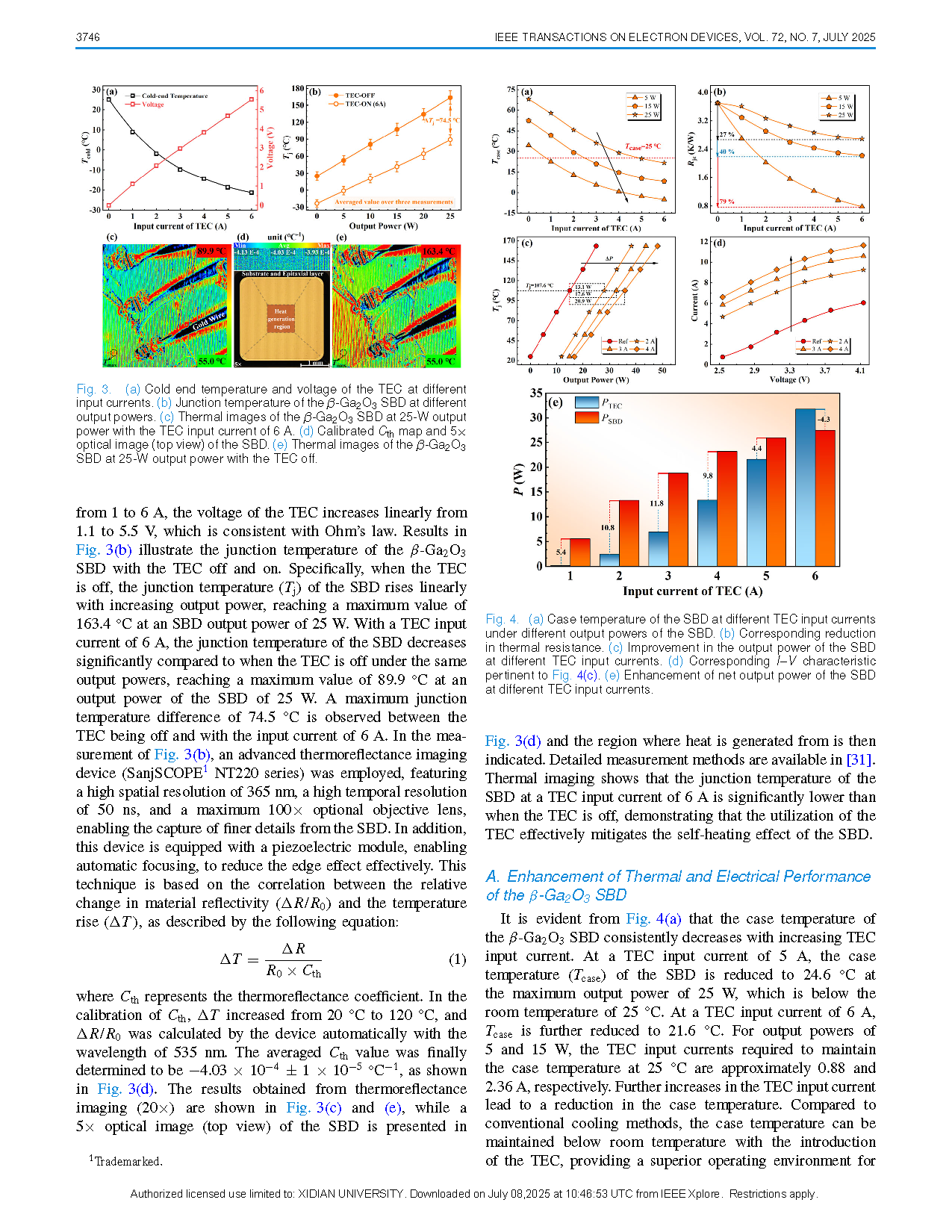

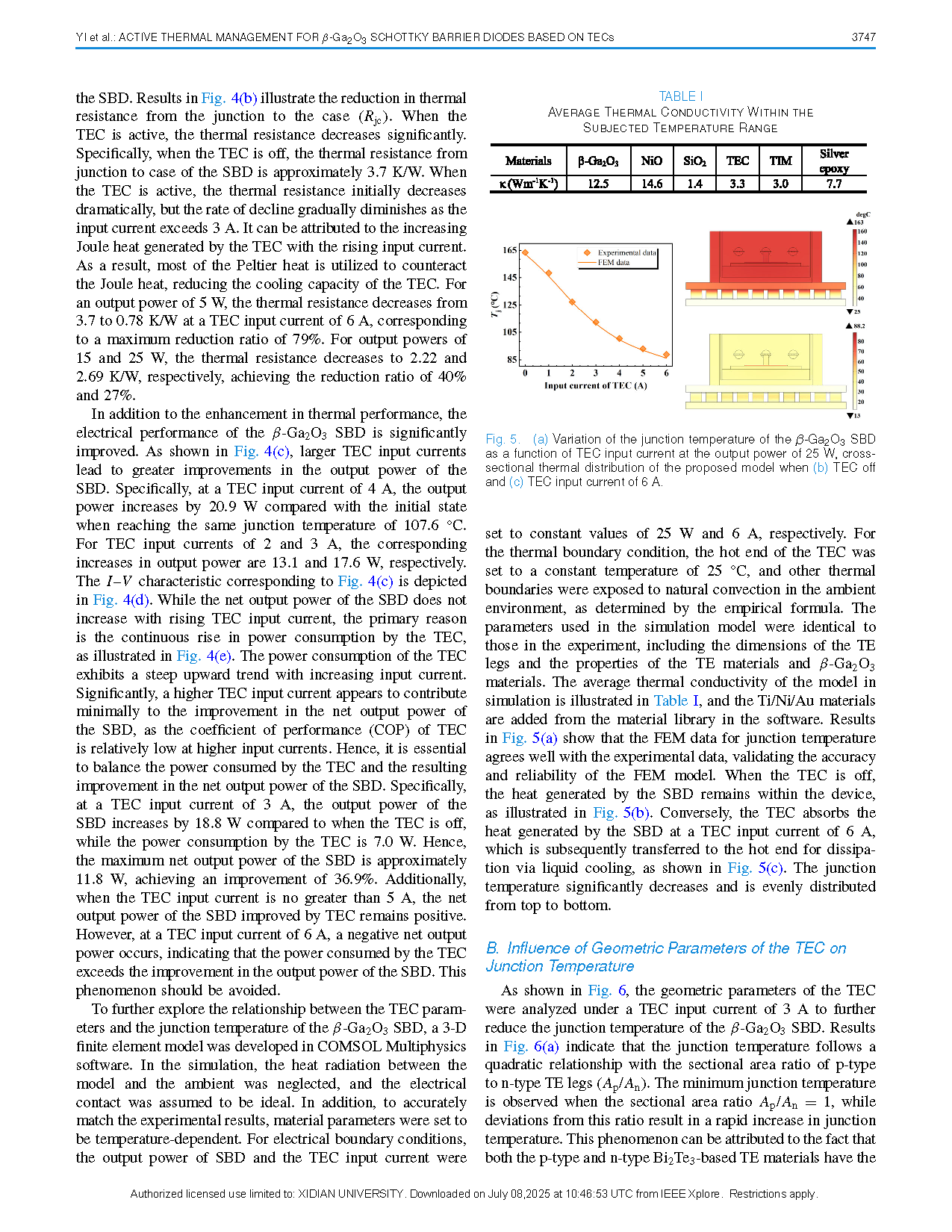

In view of the lower thermal conductivity of β-Ga2O3, effective heat dissipation is crucial for maintaining its high output power and reliability. This study presents an active thermal management model for β-Ga2O3 Schottky barrier diodes (SBDs) using thermoelectric coolers (TECs), employing both experimental and numerical methods. The heat generated by the SBD can be effectively dissipated to the surroundings through the Peltier effect in thermoelectric (TE) materials. Experimental results show that, with a TEC input current of 6 A, the case temperature remains below 25 °C even at an SBD output power of 25 W, achieving a maximum junction temperature reduction of 74.5 °C compared to when the TEC is off. At a TEC input current of 3 A, the net output power of the SBD reaches 11.8 W, corresponding to an improvement ratio of 36.9%. In simulation, TEC parameters are analyzed to optimize the junction temperature. For every 0.1-mm reduction in the height of TE legs, the junction temperature decreases by 5.3 °C. The Seebeck coefficient significantly impacts the junction temperature through co-optimization of material parameters. This work provides guidance for designing and optimizing the thermal management of β-Ga2O3 SBDs with TECs.

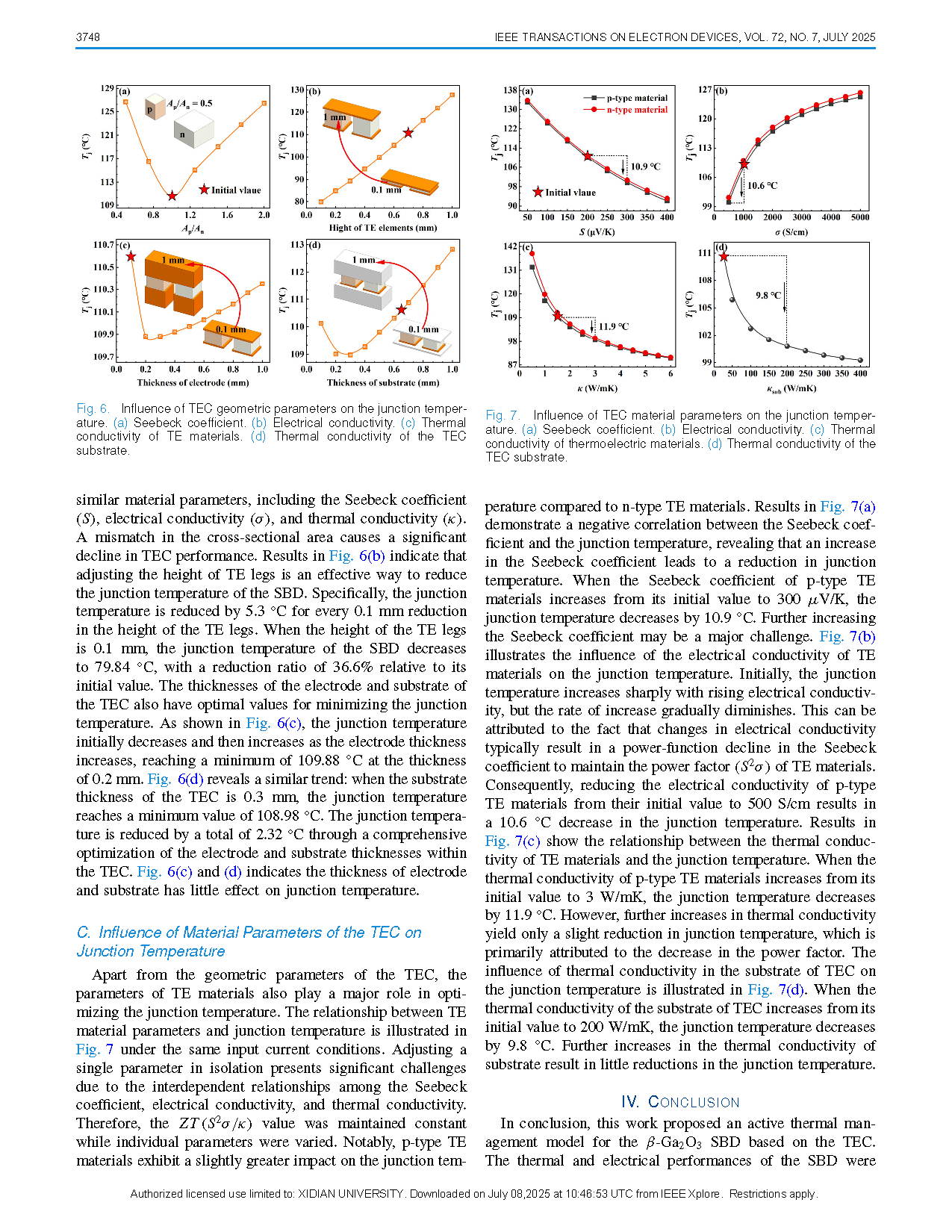

Conclusion

In conclusion, this work proposed an active thermal management model for the β-Ga2O3 SBD based on the TEC. The thermal and electrical performances of the SBD comprehensively analyzed through both experimental measurements and simulation methodologies. Experimental results indicate that at a TEC input current of 6 A and an SBD output power of 25 W, the junction temperature of the SBD is reduced by 74.5 ◦C compared to the TEC-off, achieving a maximum thermal resistance reduction ratio of 27% from junction to case. Additionally, at a TEC input current of 3 A, the maximum net output power of the SBD is approximately 11.8 W at the same junction temperature, corresponding to an improvement ratio of 36.9%.

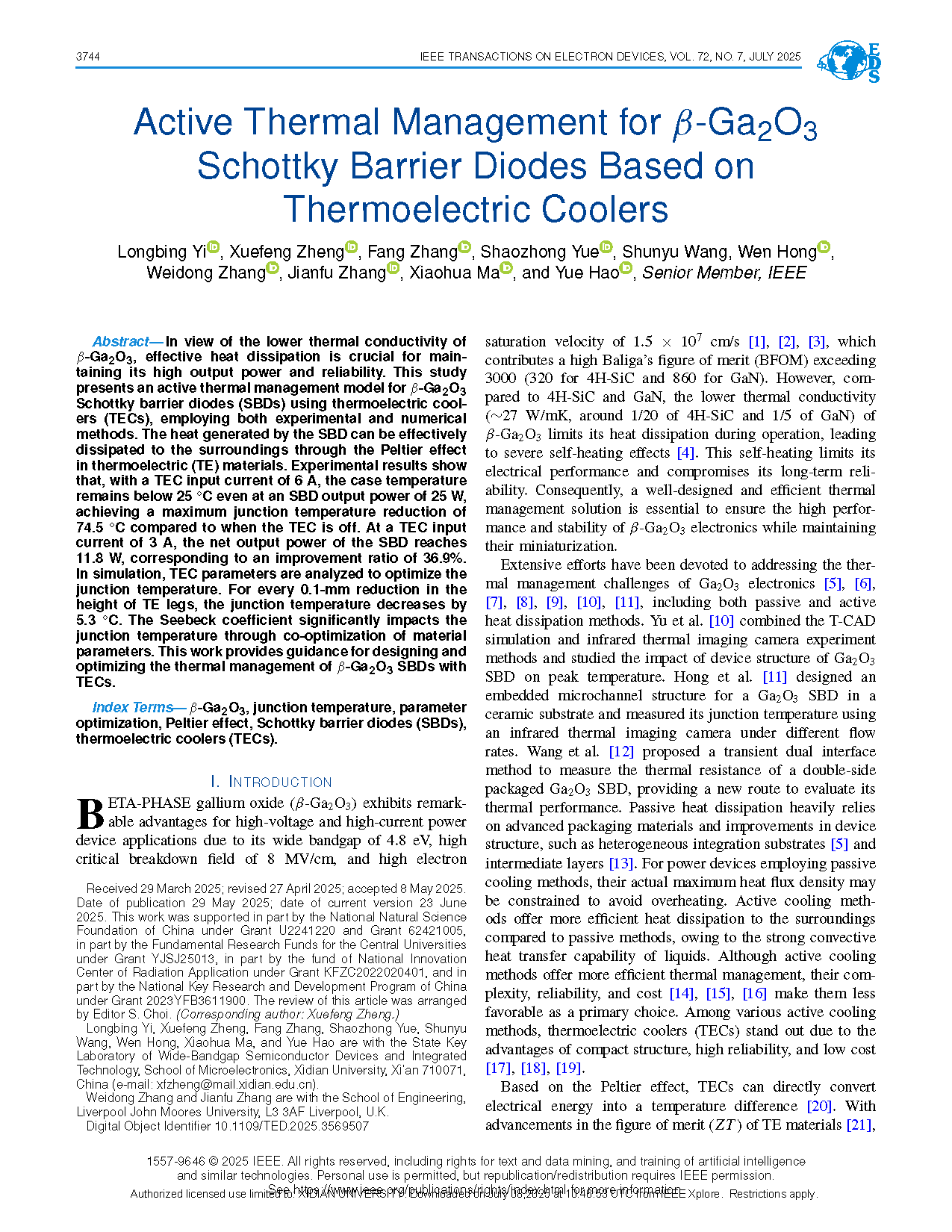

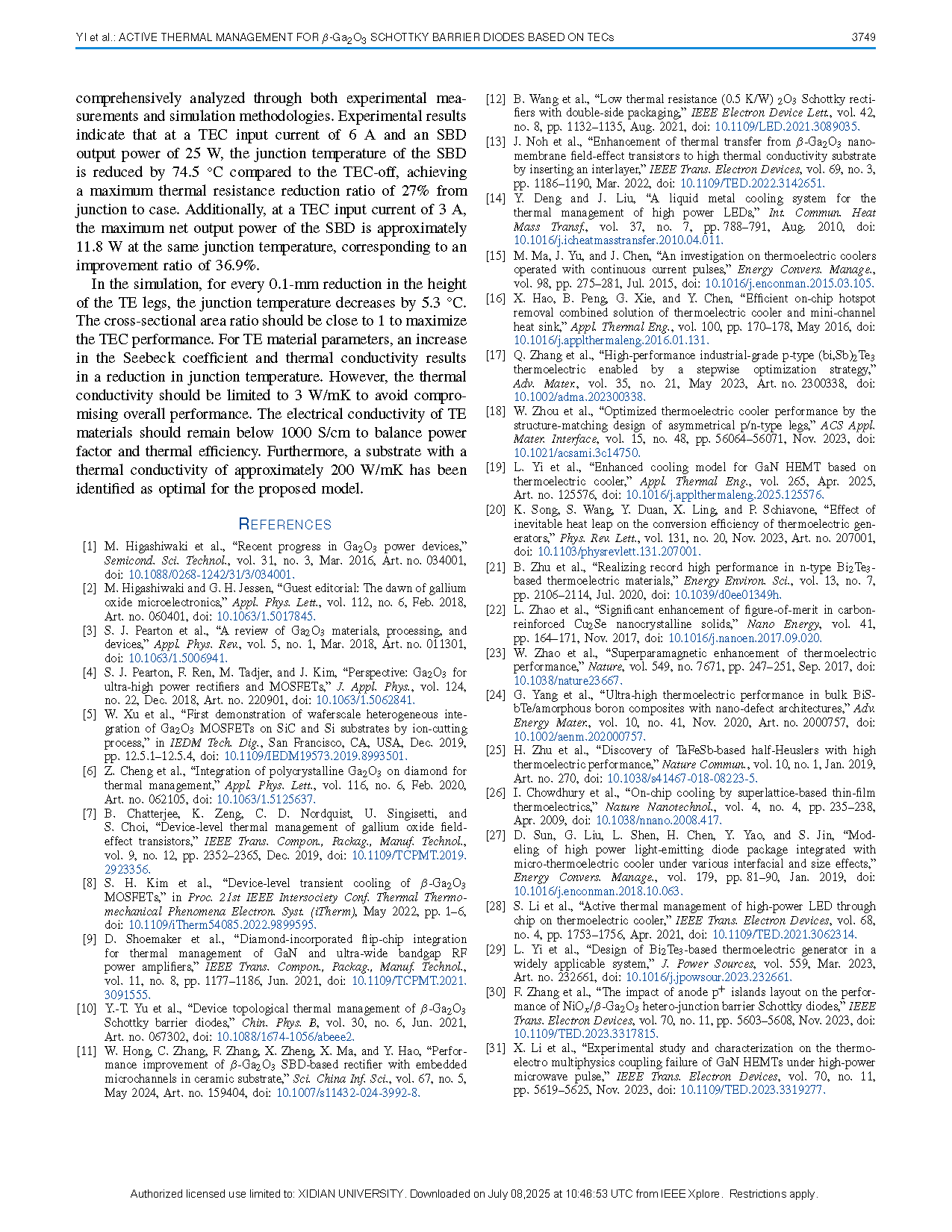

Fig. 1. Schematic of the experimental process.

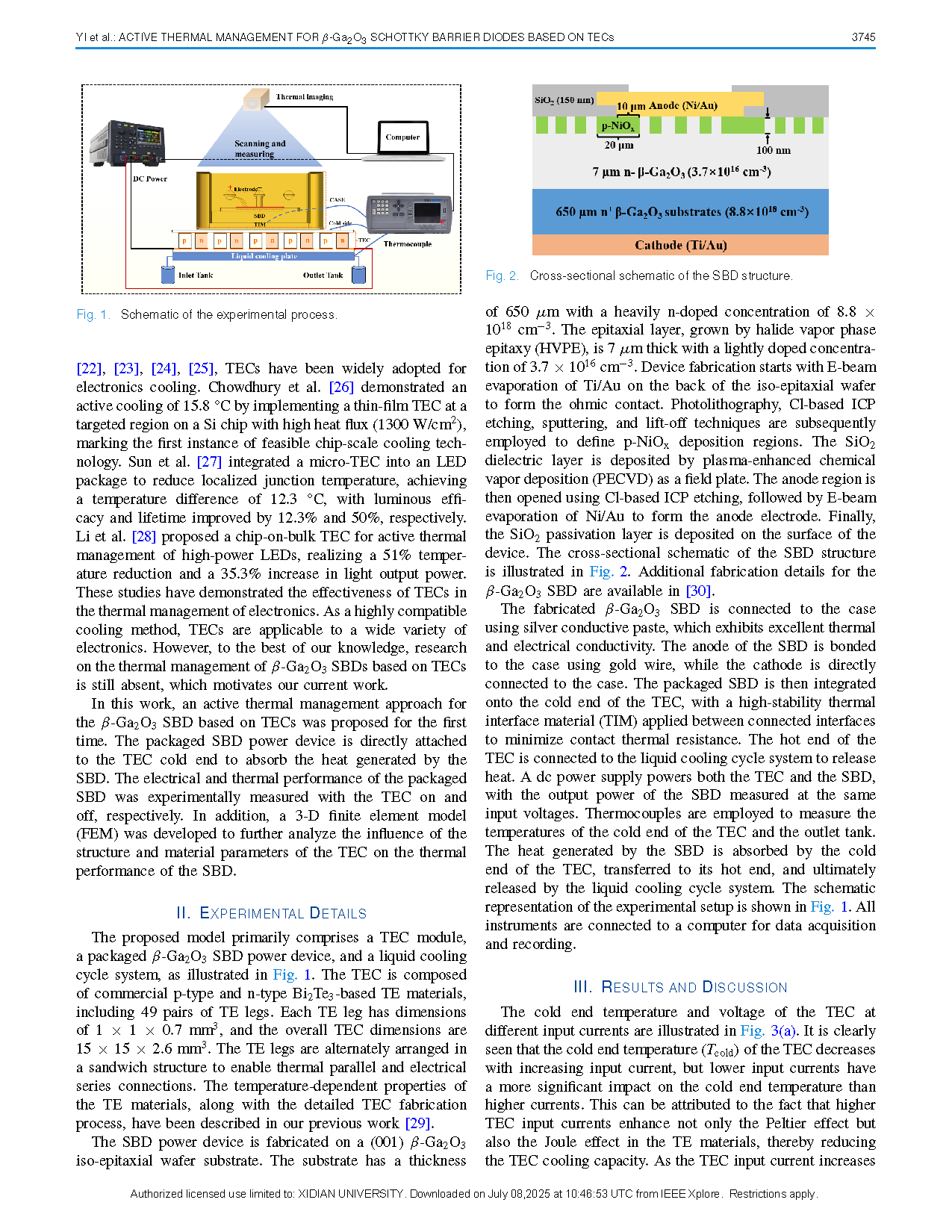

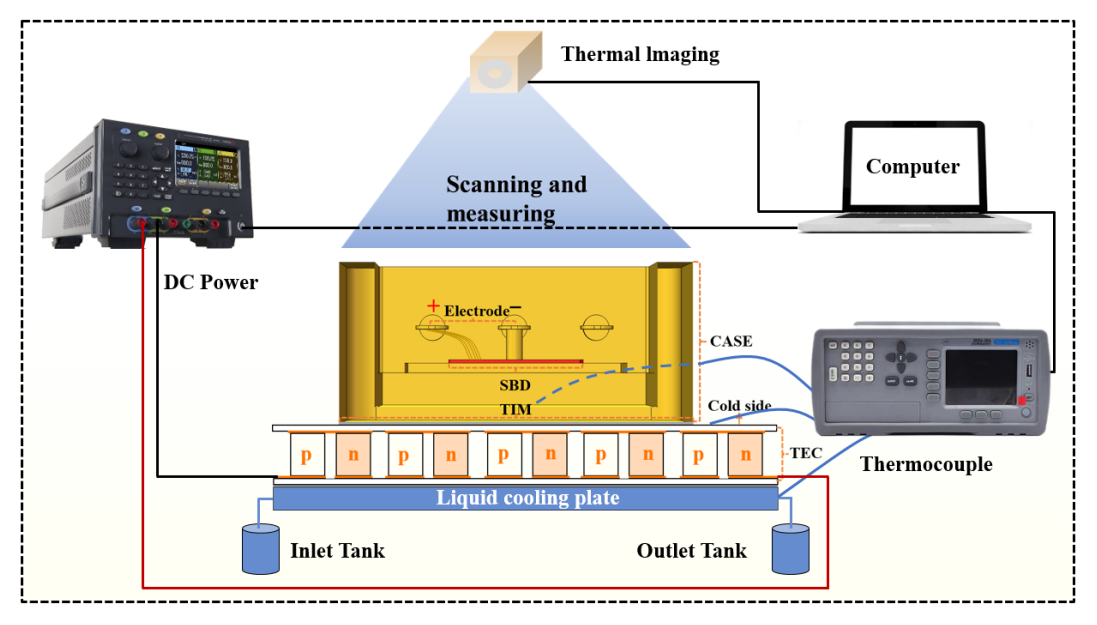

Fig. 2. Cross-sectional schematic of the SBD structure.

DOI:

doi.org/10.1109/TED.2025.3569507