【Member Papers】High performance solar blind photodetector based on β-Ga₂O₃ achieved via face-to-face thermal annealing with oxygen plasma treatment

日期:2025-07-28阅读:150

A team led by Professor Bingsheng Li from Northeast Normal University published an article entitled "High performance solar blind photodetector based on β-Ga2O3 achieved via face-to-face thermal annealing with oxygen plasma treatment" in Applied Materials Today.

Project Support

This work was supported by the National Natural Science Foundation of China under Grant 62274027 and 62404039, the Open Research Fund of Songshan Lake Materials Laboratory (2023SLABFK03) and 111 Center (B25030), the Postdoctoral Fellowship Program of CPSF (GZC20230416), the Fundamental Research Funds for the Central Universities (2412024QD010).

Background

β-Ga2O3 has emerged as an ideal material for solar-blind ultraviolet detector applications due to its ultra-wide band gap and ultra-high chemical and physical stability. The photoconductive type, which features low cost and high gain, is one of the basic structures of β-Ga2O3-based photodetector devices. However, β-Ga2O3 materials inherently contain various defects such as oxygen vacancies (VO) and gallium vacancies (VGa). These defects act as non-radiative recombination centers, affecting the transport of carriers and hindering the improvement of key device performance. Currently, thermal annealing is an effective method to improve crystal quality and reduce defect density. However, traditional annealing methods may cause damage to the surface of Ga2O3 thin films, and especially under high-temperature conditions, they may lead to the degradation of surface morphology and crystal quality. Therefore, it is crucial to develop an advanced post-treatment technology that can not only effectively eliminate internal defects but also protect the surface quality of the thin films.

Main Content

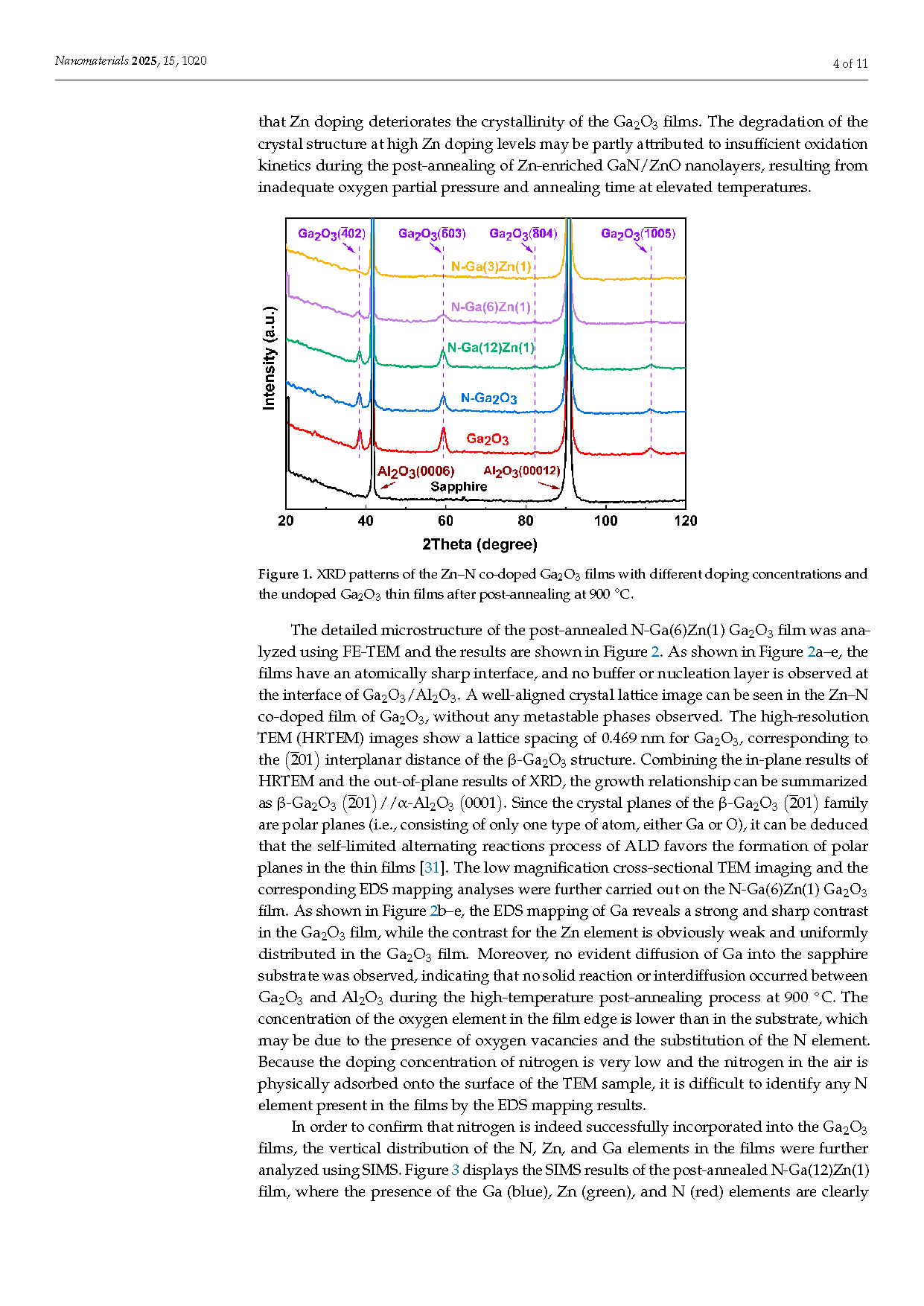

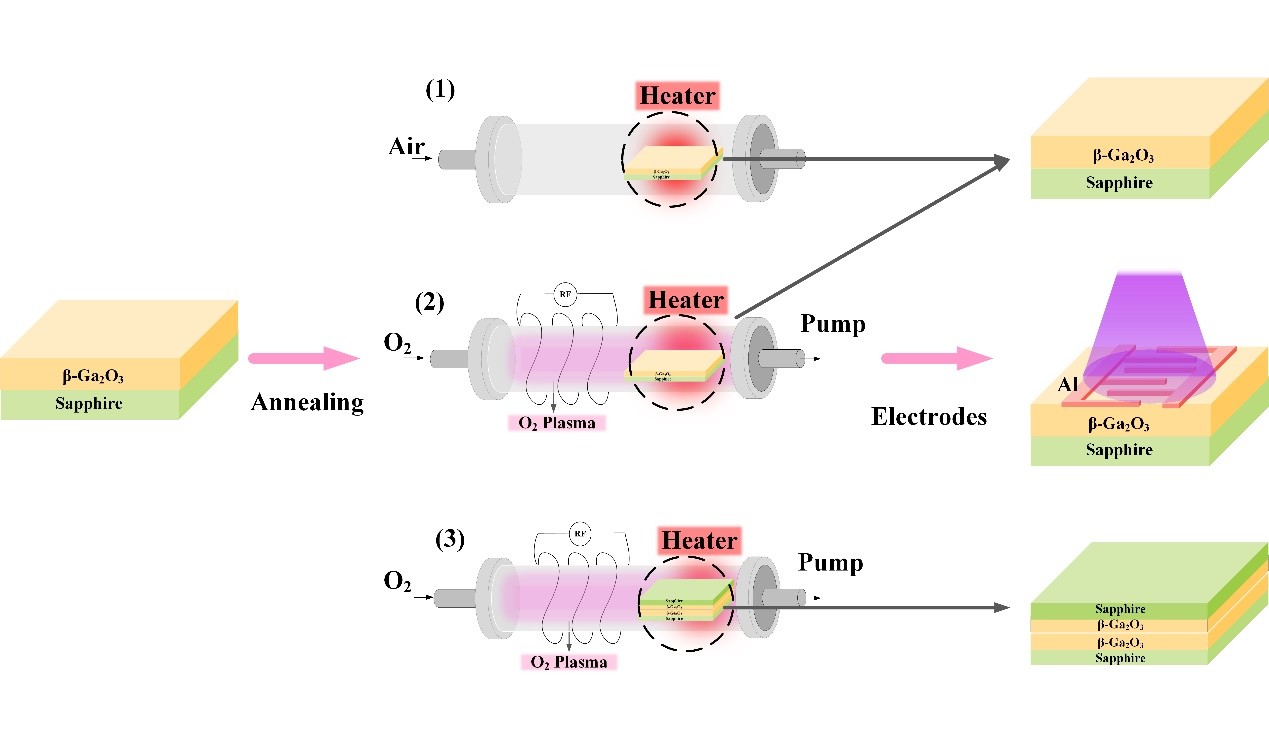

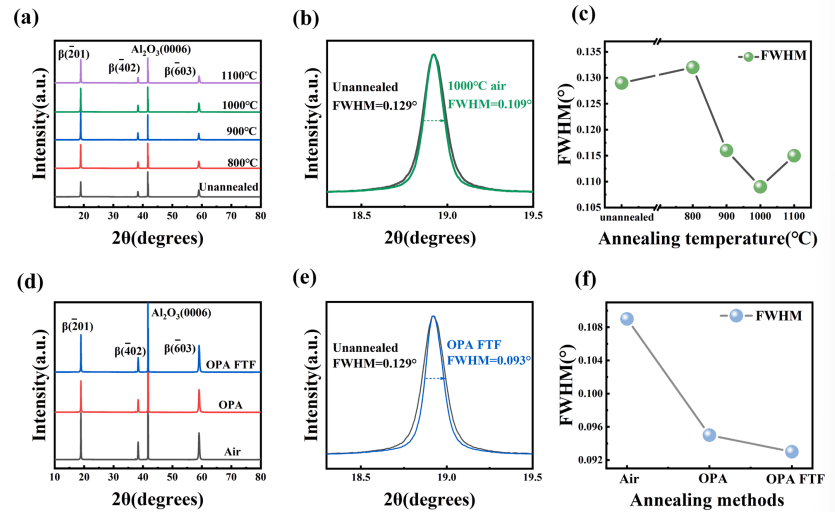

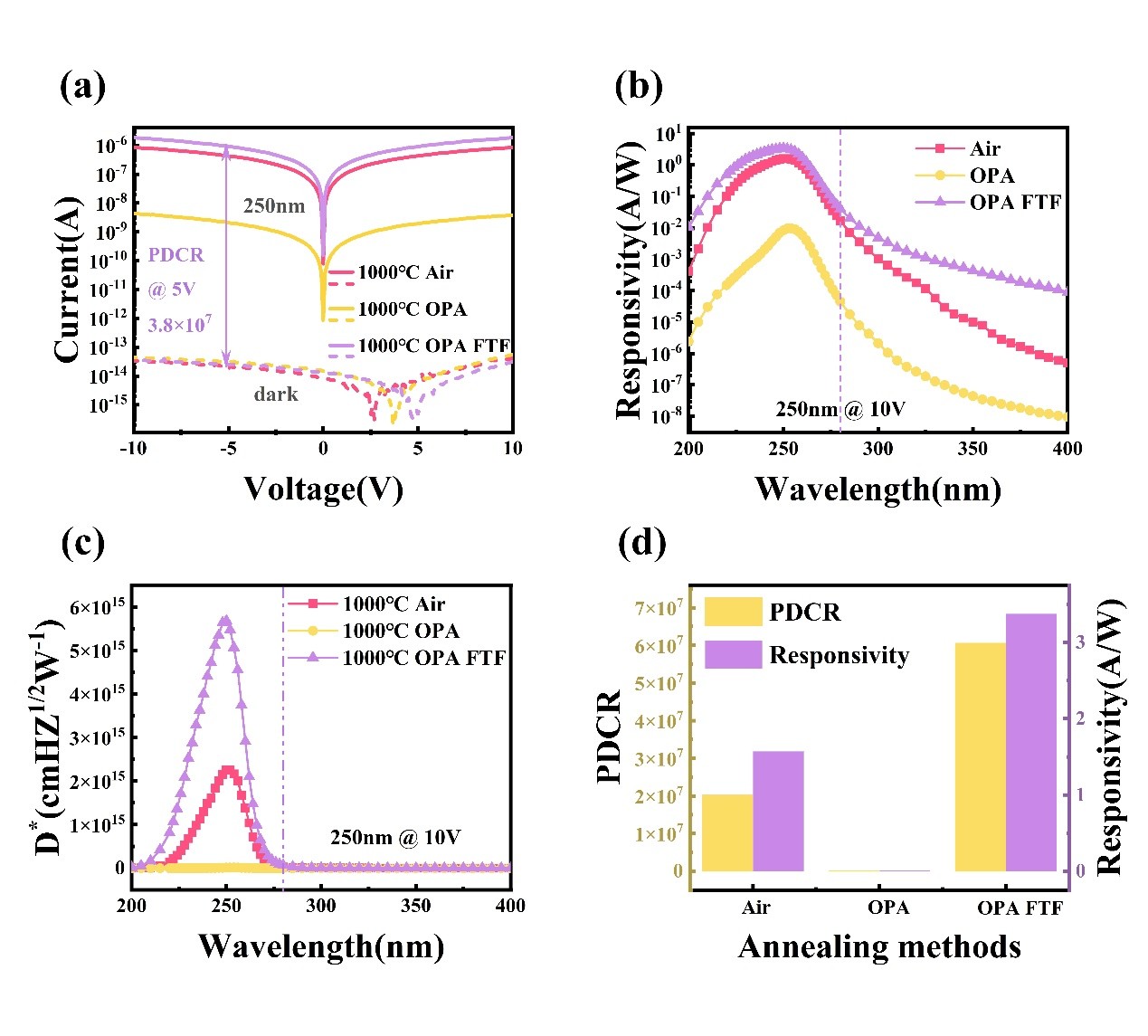

This study proposed a novel plasma face-to-face annealing process to improve the material quality and device performance. Atomic oxygen in oxygen plasma can be adsorbed on the surface and diffuse into the film more efficiently. The face-to-face sample placement can protect the surface of Ga2O3 from damage and prevent the loss/re-evaporation of oxygen from the surface. For comparison, three different annealing processes were used in this study: (1) Annealed in air. In this process, the samples were placed face-up (uncapped) in the furnace. During the annealing, air was supplied into the furnace. (2) Annealed under oxygen plasma (OPA). In this process, oxygen plasma, which was created by RF power and consists of oxygen molecules (O2), oxygen ions (O2+/-), and atomic oxygen (O), was supplied during annealing. The samples were placed face up (uncapped) in the furnace. (3) Oxygen plasma face-to-face annealing (OPA FTF). In this process, samples were placed face-to-face in the furnace, and oxygen plasma was supplied during annealing. The FWHM and root-mean-square (RMS) roughness of the β-Ga2O3 thin film treated by OPA FTF are 0.093° and 7.5 nm, respectively. The surface VO concentration decreased to 2.88%, and the VO concentration in the bulk decreased to 2.53%. The dark current of a metal-semiconductor-metal (MSM) photodetector is as low as 30 fA at 10 V bias. The device exhibits excellent performance with a light-to-dark current ratio of 6.06 × 107 and a detection rate of 5.68 × 1015 Jones. This work provides a feasible process for the preparation of high-quality β-Ga2O3 thin films.

Highlight

● The oxygen plasma face-to-face annealing (OPA FTF) technique is proposed for the first time. The sample is placed face-to-face to block high-energy ion bombardment and inhibit the re-evaporation of surface oxygen at high temperature. Avoid the surface roughness caused by traditional annealing.

● The dual regulation of surface and bulk defects was successfully achieved. The surface and internal oxygen vacancies were reduced to 2.88 % and 2.53 %, respectively. The recombination of carriers is inhibited.

● The dark current of the MSM detector is as low as 30 fA at 10 V bias, the light-dark current ratio is as high as 6.06 × 107, and the detection rate is 5.68 × 1015 The performance of β-Ga2O3-based solar blind detector is greatly improved.

Conclusion

In summary, high-quality β-Ga2O3 films and high-performance β-Ga2O3-based PDs can be obtained by post-growth annealing under optimized conditions. After annealing in air at an optimal temperature of 1000 °C, the crystallization quality was significantly improved, as indicated by the narrow FWHM of the XRD peak of 0.109°. Annealing β-Ga2O3 thin films with OPA FTF further improves the crystallization quality and surface morphology, with a FWHM of XRD peak of 0.093° and a RMS roughness of 7.5 nm. The face-to-face placement of samples protects the sample surfaces being damaged by high energy oxygen ions and prevents the loss/re-evaporation of oxygen from the β-Ga2O3 surfaces. The oxygen atoms supplied by the plasma source diffuse into the film to fill the oxygen vacancies, which effectively reduced the VO concentration in Ga2O3 from 6.26% to 2.53% when comparing to an unannealed sample. The PD fabricated from the sample annealed with OPA FTF showed improved device performance, with a relatively large PDCR of 6.06 × 107 and a high detectivity of 5.68 × 1015Jones. The device also exhibits good time response and long time stability. This is of great significance in applications that require efficient and accurate detection of UV light.

Fig 1. Process flowchart for the fabrication of β-Ga2O3 based photodetectors. Enlarged schematic drawings of the film placement during the annealing process were also shown. The three annealing processes are: (1) in air, sample face up (uncapped); (2) OPA, sample face up; and (3), OPA FTF, samples face to face.

Fig 2. (a) and (d) XRD curves; (b) and (e) magnified views of the (-201) diffraction peaks; (c) and (f) FWHMs of the (-201) diffraction peaks for an unannealed sample and samples annealed under different conditions.

Fig 3. (a) I–V curves of the PDs fabricated from β-Ga2O3 films annealed under different conditions; (b) Responsivity and (c) Detectivity of β-Ga2O3 MSM PDs; (d) Summary of PDCR and responsivity as a function of annealing process.

DOI:

doi.org/10.1016/j.apmt.2025.102851